What are stub-in and stub-on connection

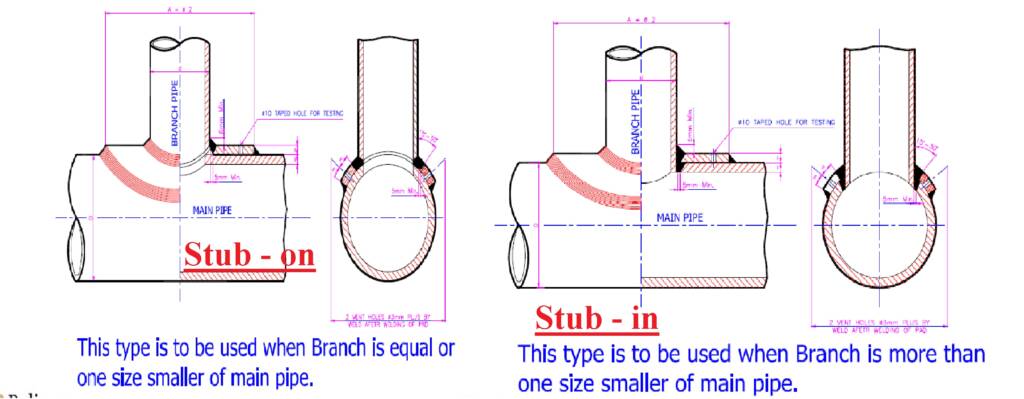

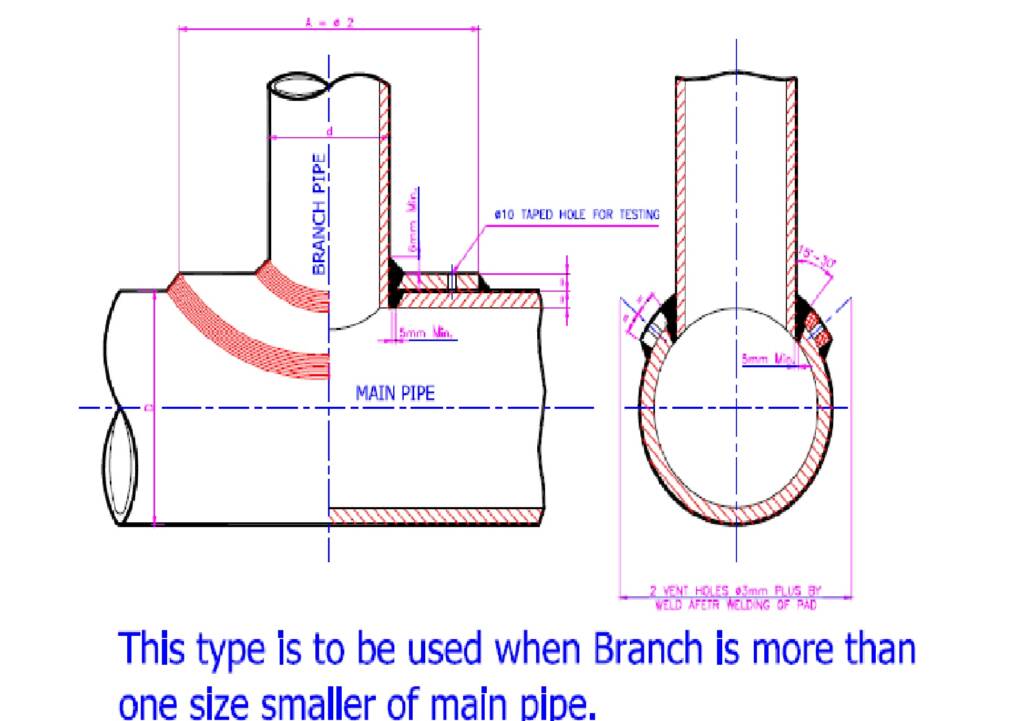

Stub-in is a type of branch from a run pipe that is fabricated by making a hole of approx 6mm larger than the outer diameter of the branch pipe. The stub-in is usually used when the branch is more than one size smaller than the main run pipe.

The measure advantages of the stub-in connection is to minimize the cost of fittings with fabrication and reduce fabrication time because for joint welding only one around with the stub hole instead of 03 around for the two part connection connections.

Used in conjunction with a backing flange, a Stub End is a short length of pipe with one flared end and one square-cut end, which is welded with pipe of the same NPS diameter, same material grade and schedule. Type A Stub Ends are fabricated and machined to fit Lap Joint flanges. Stub in and Stub on branch connections may be fabricated with or without a reinforcing pad as per end user requirement.

Why stub-in and stub-on connection required

This requirement of with or without a reinforcing pad is totally subjected to pressure and stress criteria.

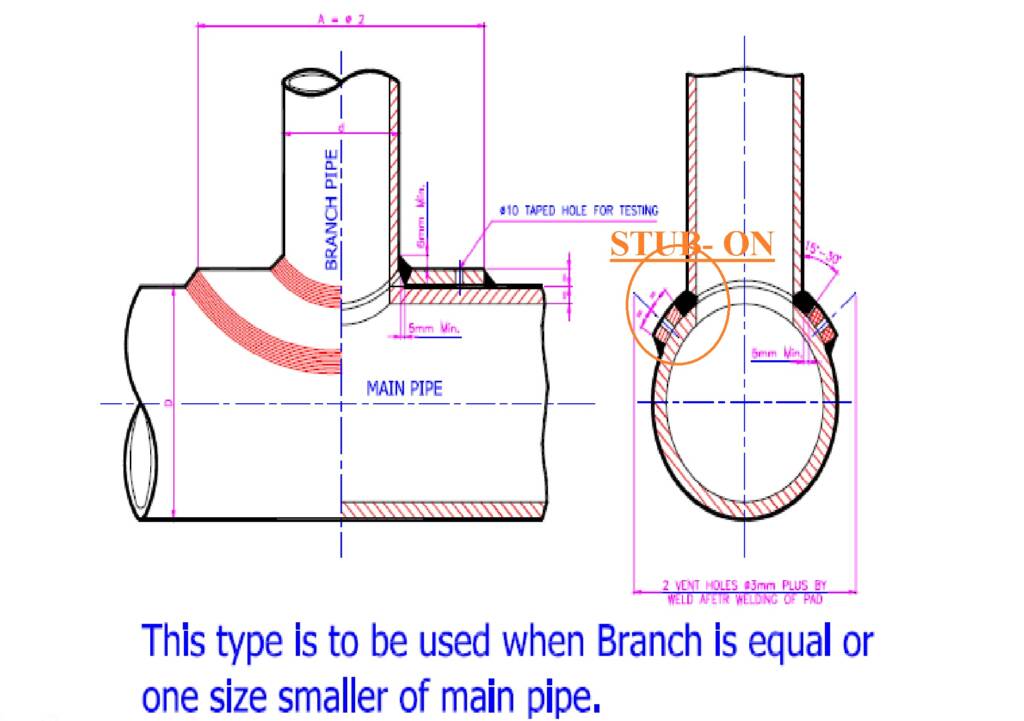

The reinforcement pad is basically a plate curved ring that is fabricated from the pipe (same as a run pipe) or from a plate with the same material grade which has to weld each other. At the center of the pad, a hole is made (the size the same as the branch pipe). When pad is cut from a flat plate it is contoured to fit around the run pipe. The width of the reinforcement pad is approx one half the diameter of the rune pipe.

The purpose of reinforcement pad is to provide straight the branch connection of the header. A small-diameter hole is made for smooth weld (prevent air trap between pad and run pipe during the welding process), and that’s hole is known as weep hole (1/4″ NPT) is normally drilled in the pad.

That welds strength of stub connection is good as butt welding but welding steps are difficult in actual conditions. So stub-in is comparatively stronger than stub on connections. During the pipings stress considerations calculation SIF of stub-on and stub-in are more than weld-olets and tees, That is play an important role during detailed stress analysis is done on the system(By software).

While analysis, extra caution needs to be considered as the stress generated will be higher and The use of both type of branch connection (stub in and stub on) is not preferred for cyclic applications, high-pressure temperature applications, or category M fluid service applications.

Types of stub connection

Stub-in connection

Stub-in is used when the run pipe and branch pipe has a difference of more than one size. In case of stub-in branch connection, the pipe welding between the branch and header is of butt-weld type. This welding is quite difficult. Able to withstand more pressure. The branch edge of a stub-in connection matches with the internal pipe diameter of the header. Usually stub in have much more weld strength than sub-on branch connections.

Stub-Out Connection

On the contrary, a stub-on pipe branch connection is applicable when the branch pipe is

equal to run pipe only one size lower than the header pipe. Stub-on branch connections are made using fillet welds. Welding is easier as compared to the stub-in welding method. Comparatively weaker than stub-in branch connection and hence, handles less pressure. For stub-on branch connection, the branch edge lies on the outside diameter of the header. but it have comparatively less weld strength value then the stub in connection.

The stub in connection is function as olets like Weldolet Fitting.

- Types-of-valve

- Application-of-butterfly-valve

- Application-of-gate-valve

- Interview-question-answer-about-glove-valve

- Globe-valve-and-its-uses

Follow the above mentioned link for read more articles.