Pipeline cleaning

Pipe line cleaning plays an important role for smooth startup of a newly installed plant and there are many methods to perform pipe line cleaning depending on its service fluid. In some cases cleaning required is very high like for oxygen line, hydrogen line, syngas and others and if foreign particles leave in pipeline during cleaning causes fire in pipeline. There are different types of sources used to clean pipe these are water, air, steam, pigging, chemical and etc. Now below we have described each type of the cleaning system which is performed in the plants.

Why is pipe line cleaning required?

There are no written specifications available to define the level of cleaning for a pipeline should be done. That means methods for measuring cleanliness have not been developed yet. Finally pipeline cleaning is a good thing and several benefits of it, that are as follows.

- Increase flow efficiency because of a smoother pipe wall.

- Prevent the equipment internals from being damaged and choking.

- Prevents services product from contamination and formation of hydrates

- Reduce abrasive damage to pipeline accessories such as valves, strainers and instruments

Method of pipeline cleanings

There are several methods of Pipeline Internal cleaning which are used nowadays as follows. and that should be selected on the basis of fluid application.

- Sand blasting

- Steam Blowing

- Chemical cleaning

- Cardboard blasting

- Pipeline cleaning with pig

- Purging with air, gas or nitrogen

Sand blasting

Sand blasting is an effective method for cleaning pipelines inside and outside the surface and other hard surfaces as well. Sands blasting is mostly used when services of fluid natural gas or petroleum products or other expensive fluid to be transferred. Generally small bore pipelines are sand blasted by using air or nitrogen to move the sand. This method is also used for surface preparation for painting.

After execution, the sandblasting pipeline should have clay blown down, dewatered and dried the complete system. The sand blew through the dust at high velocity to remove the clay, rust, scale and foreign particles. One thing is always taken care to ensure that short sections should be cleaned every time so that high velocities may be maintained and that large quantities of dry air or gas are available to maintain the high velocities.

Steam Blowing

Steam blowing is also an efficient method of pipeline cleaning. In this method steam blows in the pipeline to clean the inside surface of the pipe, same as air blow. But in steam, the blowing temperature is much higher than air and too noisy.

For check cleaning a target plant is inserted inside the pipeline and sent for lab tests to ensure that cleaning is done or not at regular intervals. Some basic terminology is used as follows.

CFR < 1.0 No target plate is used. (CFR – means that cleaning force ratio)

CFR = ( vb / vmcr ) x ( Fb / Fmcr )2 > 1.00

Where

FB = Mass flow rate at blowing, VB = Steam specific volume at blowing, VMCR = Steam specific volume at optimum load, FMCR = Mass flow rate at optimum load,

Target Plate is used to check the impacts of particles during steam blowing. Steam Blowing will be declared completed if the following criteria are observed on target plates that are.

- Diameter of impact not more than 1 mm or

- If 4 impacts diameter not more than 0.5 mm or

- 10 impacts diameter not more than 0.2 to 0.5 mm

- Clean White Smoke should be observed at the Exhaust of Tail Pipe or muffler.

There are some basic arrangements required for steam blowing; these are as below. Pressurized steam source, target plate, tail pipe, temporary pipeline to outside of plants, fastener and etc.

Chemical cleaning

Chemical clean is also one of the most useful methods of cleaning by using some chemical and that is typically used for small bore pipelines. We can achieve very good cleaning by a properly planned chemical cleaning process. But in this cleaning process rust could be removed from internal pits.

Chemical cleaning is done by flow of the hydrochloride acid with water mixture for the rust removal, a neutralizer and a passivator, all are separated by pig through inside the pipe line and achieved bright metal finished inside the pipelines.

If the same pipeline uses two different services back to back like crude service line changes for any chemical services than detergent can be added during the cleaning process for removal of all traces of crude oil or any other product.

This type of cleaning is also done for some special equipment, but disposing of materials is big issue so be careful during cleaning. It should be done your exercise on sampling and test the circulation mixture on regular interval that pipeline metals will not be consumed by chemicals.

There are some important chemicals which are used in the cleaning process, sodium hydroxide (NaOH)-0.05 %, sodium carbonate (Na2CO3)-0.3 % Tri-sodium phosphate (Na3PO4)-0.3 %, detergent-0.05 %. Equipment required for chemical cleanings are a storage tank for storing and mixing of chemicals, a pump set for mixture circulation inside the pipeline, jump over to connect the pipeline and chemical mixture with water.

Cardboard blasting

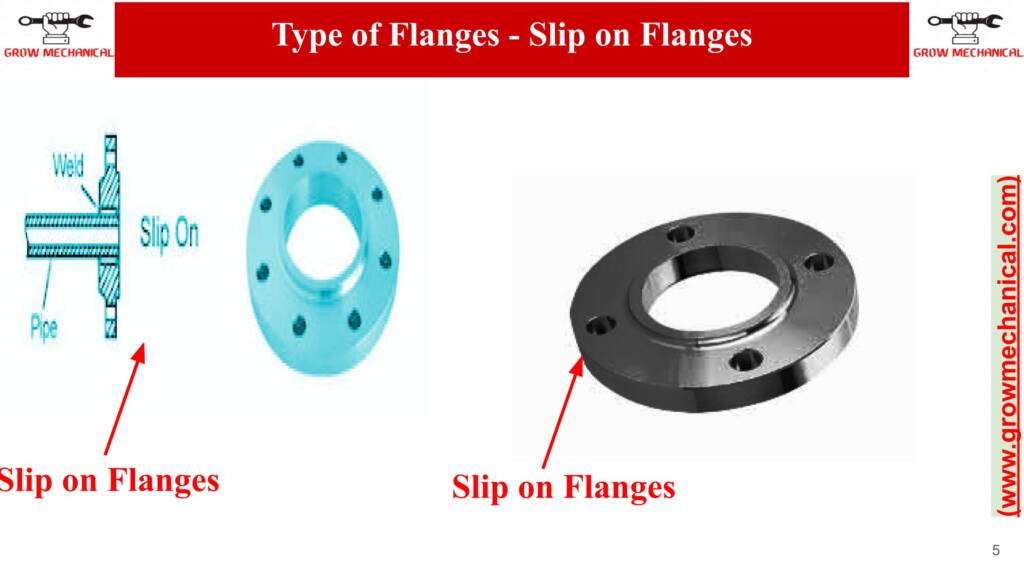

This is also an important method for removing dust, foreign particles, rust from inside the pipeline. In this arrangement some basic things are required to perform like cardboard, fastener, and compressed air or other gas As shown in the figure.

In this method select two end points of the pipeline which need to clean and fix cardboard at one end of the pipe with ring flange. Place cardboard between pipe flange and ring flange and tighten with fastener. Other end should be install blind flange with a nipple arrangement for air fill up. Then start air filling till cardboard does not bust. Again two cardboard fixed filling the air till both cardboard does not bust. This process repeats again and again till the pipeline does not clean and add one card board each time. Some special cases instead of cardboard metal thin plates are also used as per user requirements.

Purging with air or nitrogen or other gas

Purging of gas is also a cleaning method for small debris and particles by flowing the high velocity gas or air inside the pipeline. This process is done mostly with petrochemical and neutral gas transfer pipelines like propylene and ethylene that must be dried as a product. This method is used for both drying out and cleaning the pipelines as well. Natural gas pipelines usually dry out to prevent the formation of hydrates. But that is not usual for petrochemical lines to be dried to a dew point of -80F and carbon dioxide line dry may on -40F.

There are several methods used for dried out and clean the pipeline theses are as follows.

- Use by super dry air

- Inside sand blasting

- By using the methanol

- Dry out with the same services fluid

- Dry out with inert gas, like nitrogen

- Cleaning and dry with vacuum method

All of the above mentioned methods are cheaper or expensive to each other depending on your budget. You can select which are best suited for you and your application.

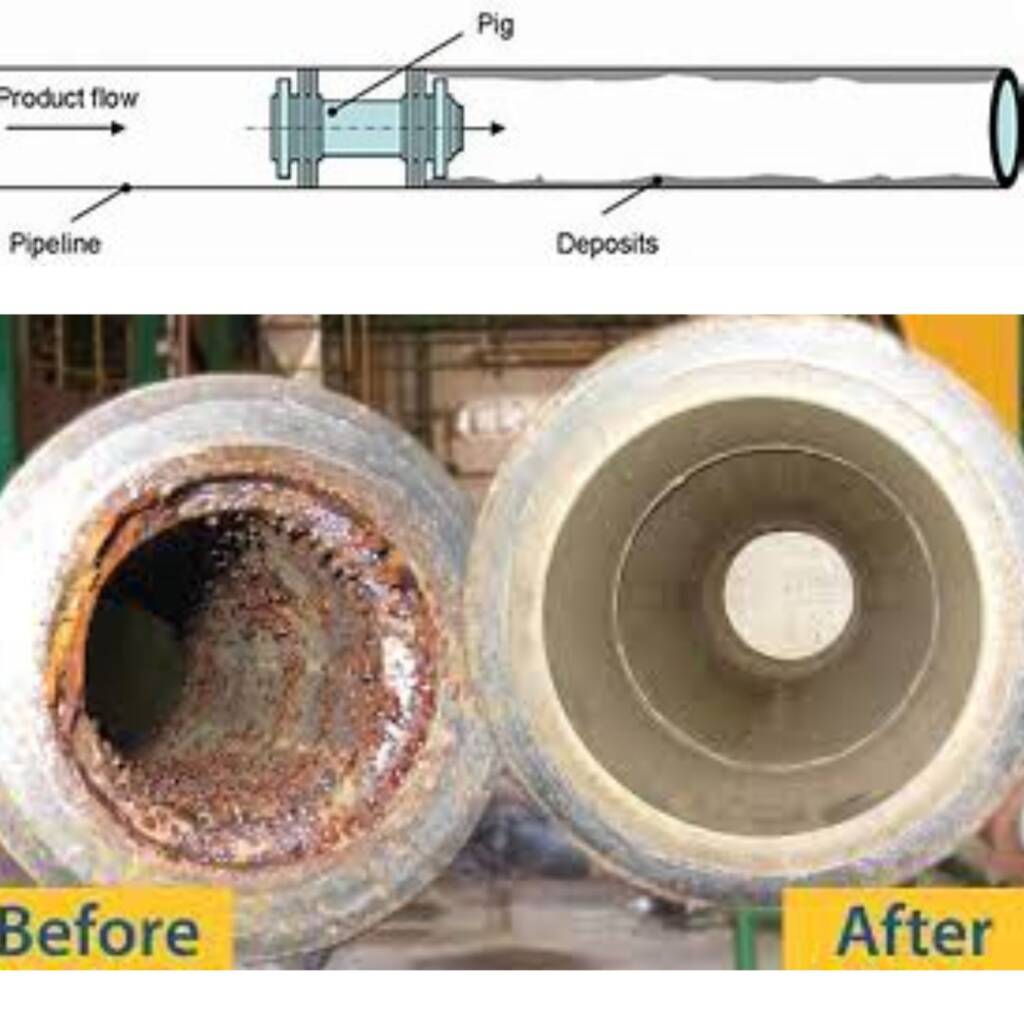

Pipeline cleaning with pig

First select two end points of pipeline one will be sender and another is receiver then placing the pig inside and pushed by gas or air. But single pigs are not able to remove small debris in pipelines so sometimes 3-4 types of pig are used 2-4 times depending on the degree of cleaning required. If the debris or particle is wet the brush pig will more smoothly clean the debris from the pipe’s internal wall, which will improve pipeline flow efficiency so before starting moving the pig in pipeline also move water.

A pig’s move with the help of water is very efficient for cleaning debris from the inside pipeline. But some precautions should be taken while the pig moves by water because the pig velocity is greater than three feet per second. Generally pigging is done for big bore pipelines. Before starting pigging all accessories like valve, strainer, NRV should be dismantled and installation should be done once pigging is done.

As shown in figure Brush Pig bypasses some of the liquid and keeps the bristles clean and moves the loose foreign particle or debris into suspension in the liquid in front of the pig. In this case it is not necessary that the pipeline be completely filled with water. Issue facing during removal of the dirty liquid due to environmental problems or contamination issues in this case should be the use of holding tanks. The gels have been developed and that is more effective than water.

Some basic types of pig are Soft Foam, Medium and High Density Foam, Polyurethane Coated Criss Cross type, Wire Brush or Power Brush type foam, Steel and Plastic Stud etc.