Agitator Introduction

An agitator and a mixer are both mechanical devices used in various industries and applications to mix or blend substances. While they share similarities, there are some differences between the two.

Agitator:

An agitator is a device used to stir or mix liquids, typically in tanks or vessels. It consists of a rotating impeller or blade that creates turbulence in the liquid, promoting mixing and ensuring uniform distribution of the substances. Agitators are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. They are often used for tasks such as blending liquids, suspending solids in liquids, or promoting heat transfer within a system.

Mixer:

A mixer, on the other hand, is a broader term that encompasses a variety of devices used to combine different substances or ingredients. Mixers can be used for liquids, solids, or a combination of both. They are employed in industries such as food processing, cosmetics, pharmaceuticals, and construction. Mixers can range from simple handheld devices, such as handheld mixers used in cooking, to more complex industrial-scale machines. They can be designed for specific applications, such as high-speed mixing, emulsifying, or dispersing.

While both agitators and mixers are used for mixing substances, the key difference lies in the scale and purpose of their applications. Agitators are primarily used in large-scale industrial processes, often in tanks or vessels, where uniform mixing and circulation are required. Mixers, on the other hand, can range from small handheld devices to larger machines and are used in various settings, including laboratory experiments, small-scale production, and commercial manufacturing.

It’s worth noting that the terms “agitator” and “mixer” are sometimes used interchangeably, and the specific terminology may vary based on industry or context.

- To produce static or dynamic uniformity in multi component multi phase systems. E.g. Blending of liquids.

- To facilitate mass or energy transfer between parts of a system not in equilibrium.

- To promote phase change in a multi component system with or without change in composition. E.g. Homogenization, gas dispersion and crystallization.

Impeller of agitators

The impeller is a key component of agitators. It is a rotating device that is responsible for creating fluid flow and promoting mixing within a tank or vessel. The impeller’s design and characteristics determine the type and effectiveness of mixing achieved.

Impellers are typically made of various materials such as stainless steel, cast iron, or plastic, depending on the application and the properties of the substances being mixed. They are engineered with specific blade shapes, sizes, and configurations to suit different mixing requirements.

Some common types of impellers used in agitators include:

- Propeller Impeller: This type of impeller consists of multiple flat blades that resemble a propeller. It is commonly used for low-viscosity fluids and provides good axial flow, creating a pumping effect.

- Turbine Impeller: Turbine impellers have curved blades that generate both axial and radial flow. They are suitable for a wide range of viscosities and are often used for blending, solids suspension, and heat transfer.

- Paddle Impeller: Paddle impellers feature flat or curved blades that extend radially from a central hub. They are effective in mixing high-viscosity fluids, viscous slurries, or non-Newtonian fluids.

- Anchor Impeller: Anchor impellers consist of a central shaft with blades that resemble an anchor. They are primarily used for viscous or shear-thinning fluids and are well-suited for scraping the vessel walls and ensuring thorough mixing.

- High-Shear Impeller: High-shear impellers, such as the sawtooth or axial flow impellers, are designed to create intense shear forces for emulsification, dispersion, and particle size reduction.

The selection of the impeller type depends on factors like the desired mixing intensity, the viscosity and characteristics of the fluid, the vessel size and shape, and the process requirements. The design and installation of the impeller in the agitator system are crucial for achieving efficient and homogeneous mixing in industrial applications.

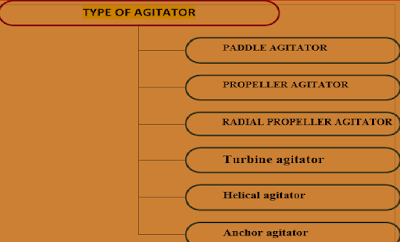

Types of agitator

There are several types of agitators used in industrial applications, each designed to meet specific mixing requirements. Here are some common types of agitators:

- Top-Entry Agitators: These agitators are mounted on the top of a tank or vessel and are suitable for large-scale applications. They generally consist of a motor-driven shaft with an impeller that extends into the liquid. Top-entry agitators are commonly used for mixing large volumes of liquids, suspending solids, or promoting heat transfer.

- Side-Entry Agitators: Side-entry agitators are installed through the side wall of a tank or vessel, typically at or below liquid level. They are commonly used in large tanks where top access is limited. Side-entry agitators are often used for blending, solid suspension, and maintaining uniformity in tanks with high aspect ratios.

- Bottom-Entry Agitators: These agitators are mounted at the bottom of a tank or vessel, usually through a nozzle or a flange. They are designed to create upward flow and circulation, promoting efficient mixing and preventing settling of solids at the bottom. Bottom-entry agitators are commonly used in applications where solids tend to settle or where heat transfer from the vessel wall is important.

- Magnetic Agitators: Magnetic agitators use a magnetic coupling to transmit the rotational motion from an external drive to the impeller inside the vessel. This design eliminates the need for a shaft penetrating the tank, making them suitable for applications that require aseptic conditions or when leakage prevention is critical.

- Static Mixers: Static mixers are devices that use stationary elements, such as baffles or vanes, to create mixing. They do not have any moving parts and rely on the flow of fluids through a series of mixing elements to achieve blending and dispersion. Static mixers are often used for continuous mixing processes and can be installed inline within a pipeline.

- Jet Agitators: Jet agitators use a high-velocity fluid stream to create mixing within a tank. They work by entraining surrounding liquid and creating circulation through the impact of the jet. Jet agitators are commonly used in applications where high shear mixing or rapid dispersion is required.

The selection of the appropriate agitator type depends on various factors, such as the mixing task, vessel geometry, viscosity of the fluid, desired mixing intensity, and process requirements. It’s important to choose the right agitator to ensure efficient and effective mixing in industrial processes.

Here’s a description of the agitators you mentioned:

Paddle Agitator: The paddle agitator features flat or curved blades that extend radially from a central shaft. It is often used for blending high-viscosity fluids, viscous slurries, or non-Newtonian fluids. Paddle agitators provide gentle mixing and are effective in promoting heat transfer.

Propeller Agitator:

Propeller agitators have multiple flat blades that resemble a propeller. They are commonly used for low-viscosity fluids and provide good axial flow, creating a pumping effect. Propeller agitators are suitable for applications such as blending, suspending solids, and promoting uniform circulation.

Radial Propeller Agitator:

A radial propeller agitator is a variation of the propeller agitator. It consists of blades that are inclined at an angle to the shaft, creating both radial and axial flow. This type of agitator is particularly useful for tanks with a high aspect ratio and provides efficient blending and circulation.

Turbine Agitator:

Turbine agitators have curved blades that generate both axial and radial flow. They are versatile and can be used for a wide range of viscosities. Turbine agitators are commonly employed for blending, solids suspension, heat transfer, and maintaining uniformity in the vessel.

Helical Agitator:

Helical agitators feature a helix-shaped blade that wraps around a central shaft. The helical design provides gentle agitation, making it suitable for shear-sensitive fluids or fragile materials. These agitators are often used in applications that require low shear and gentle mixing.

Anchor Agitator:

Anchor agitators consist of a central shaft with blades that resemble an anchor. They are primarily used for high-viscosity or shear-thinning fluids. Anchor agitators scrape the vessel walls, ensuring thorough mixing and preventing solids from settling at the bottom of the tank.

These agitator types offer different mixing characteristics and are chosen based on factors such as fluid properties, vessel geometry, and desired mixing outcomes in various industrial processes.

Difference between Agitator and mixer

Function:

Agitators are primarily designed to create fluid movement and promote mixing within a tank or vessel. They are focused on generating turbulence and circulation to ensure uniform distribution of substances. Mixers, on the other hand, have a broader function. They are used to combine different substances or ingredients, whether in liquid, solid, or a combination of both forms.

Scale and Application:

Agitators are commonly used in large-scale industrial processes, often in tanks or vessels. They are frequently employed in industries such as chemical processing, pharmaceuticals, and wastewater treatment. Mixers, on the other hand, can range from small handheld devices used in cooking to larger machines used in commercial manufacturing. Mixers find applications in various industries such as food processing, cosmetics, pharmaceuticals, and construction.

Design and Configuration:

Agitators typically consist of a rotating impeller or blade that is attached to a shaft and driven by a motor. The impeller creates fluid flow and agitation within the tank. Mixers, on the other hand, can have different designs and configurations depending on the specific application. They can include devices such as handheld mixers, paddle mixers, high-shear mixers, or static mixers.

Mixing Intensity:

Agitators are generally focused on achieving consistent and uniform mixing within a tank or vessel. They are designed to provide gentle or moderate mixing, ensuring proper blending, suspension of solids, or heat transfer. Mixers, on the other hand, can offer a range of mixing intensities depending on the specific type. Some mixers are designed for high-speed mixing, emulsification, dispersion, or particle size reduction, allowing for more intense and thorough mixing.

When selecting an agitator or mixer for a specific application, several parameters and considerations should be taken into account. Here are some key factors to consider:

Mixing Objective:

Clearly define the purpose of mixing, whether it is blending, suspending solids, promoting heat transfer, or achieving a specific level of homogeneity. This will help determine the type of agitator or mixer needed.

Fluid Properties:

Understand the characteristics of the fluid or substances being mixed, such as viscosity, density, shear sensitivity, and corrosiveness. These properties will influence the selection of the agitator or mixer design, material of construction, and power requirements.

Tank or Vessel Geometry:

Consider the size, shape, and dimensions of the tank or vessel in which the mixing will take place. Factors such as aspect ratio, baffles, and bottom or side entry will affect the choice of agitator or mixer configuration.

Mixing Intensity:

Determine the required mixing intensity or energy input for the process. This can be influenced by factors such as desired blending time, degree of agitation, and shear forces required. Different agitators and mixers offer varying levels of mixing intensity.

Speed and Power Requirements:

Evaluate the speed and power necessary to achieve the desired mixing results. This includes considering the rotational speed of the agitator or mixer, motor power, and torque requirements. Higher viscosity fluids or heavy loads may require more powerful equipment.

Material Compatibility:

Ensure that the agitator or mixer materials are compatible with the fluids or substances being mixed. Consider factors such as chemical compatibility, resistance to corrosion or abrasion, and compliance with industry standards or regulations.

Maintenance and Cleanability:

Assess the ease of maintenance and cleanability of the agitator or mixer. Consider factors such as accessibility for maintenance, ease of disassembly and reassembly, and the ability to meet hygiene or sterilization requirements, especially in industries like food or pharmaceuticals.

Cost Considerations:

Evaluate the initial investment cost, operational costs, and potential long-term maintenance expenses associated with the agitator or mixer. Consider the overall cost-effectiveness and return on investment.

Industry and Application-specific Requirements: Take into account any specific requirements or standards dictated by the industry or application. Certain industries, such as pharmaceuticals or food processing, may have stringent regulations or guidelines that need to be met.

By considering these parameters and considerations, you can select the most suitable agitator or mixer for your specific application, ensuring optimal mixing performance and efficiency.