ASTM A216 Gr WCB

ASTM A216 Gr WCB is a versatile material that is commonly used in fabrications and welding operations. With its superior strength and high ductility, this material provides many advantages for a wide range of applications. Learn more about the properties of ASTM A216 Gr WCB and its benefits in this guide.

What is ASTM A216 Gr WCB?

ASTM A216 Gr WCB is a type of casting alloy made up of iron and carbon, developed to meet the demands of applications requiring high strength and excellent resistance to corrosion. This material offers superior wear and heat-resistance capabilities and is commonly used in demanding fabrication scenarios when welding operations are required.

Key Benefits of ASTM A216 Gr WCB

ASTM A216 Gr WCB offers several benefits when used in fabrication and welding operations. It is known for its superior strength, excellent corrosion resistance, and superior wear-resistance capabilities. In addition, this type of alloy is incredibly easy to work with and can be cut, machined or welded with ease. Furthermore, it provides an excellent bonding surface due to its ability to retain heat energy during welding operations.

Uses of ASTM A216 Gr WCB in the Petrochemical Industry

ASTM A216 Gr WCB is a particularly useful material in the petrochemical industry, due to its superior corrosion resistance and superior wear-resistance. This type of alloy is often used in the manufacture of vessels, pipe fittings, centrifuges, valves, pumps, and other components of machines used in oil refineries and petrochemical plants. Furthermore, it can also be used as an effective lining for tanks containing hydrocarbons or other hazardous materials.

Welding of ASTM A216 Gr WCB and Typical Welding Procedure Recommendations

Welding of ASTM A216 Gr WCB is highly effective, and welders have a few processes available to them when fabricating with this material. Shielded Metal Arc Welding (SMAW) and Gas Tungsten Arc Welding (GTAW) are the two most commonly used techniques for welding ASTM A216 Gr WCB components. For optimal results, operators should use GTAW as it provides an inert shielded environment that helps reduce chemical exposure while it also produces minimal thermal distortion compared to SMAW.

Applications, Dimensions and Specifications for ASTM A216 Gr WCB Steel Castings

ASTM A216 Gr WCB steel castings are suitable for use in a wide range of applications, including those subject to high temperature and pressure. The material is available in a range of dimensions and specifications including dimensions that range from 1.50 inches to 8 inches with wall thicknesses 1/8 inches and up. Standard grades are listed as Grade B and Grade C, but custom grades can also be specified for special applications.

Material Properties

- ASTM A216 Grade WCB is a high-density steel alloy with a density of 7.82 g/cm3 (or 488 lb/ft3).

- ASTM A216 Gr WCB is a grade of steel with an elastic modulus of 210 GPa (30 x 106 psi).

- ASTM A216 GR WCB refers to the grade of steel used in manufacturing.

- This grade of steel has an elongation value of 25% when it is subjected to a tensile stress test.

- The Specific Heat Capacity of ASTM A216 Gr WCB is 450 J/kg-K.

- ASTM A216 gr WCB is a steel grade that boasts a strength-to-weight ratio of 73 kN-m/kg.

- ASTM A216 Grade WCB is a carbon steel material that has a ultimate tensile strength of 570 Megapascals (MPa) or 83 thousand pounds per square inch (103 psi).

- ASTM A216 Gr WCB is a steel alloy with a yield strength of 280 MPa (41×103 psi).

- ASTM A216 Gr WCB has a thermal expansion coefficient of 11.9 µm/m-K.

- which is the amount it expands for each degree Kelvin increases in temperature.

|

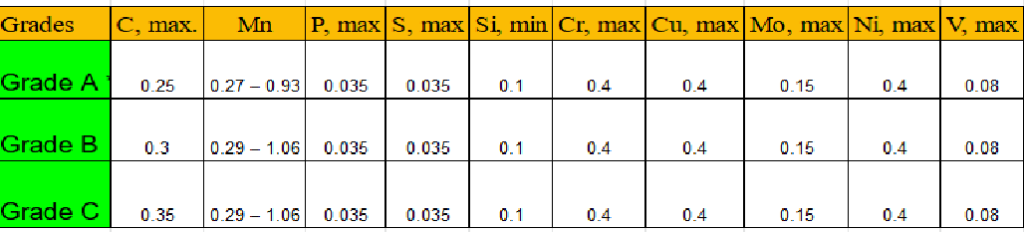

ASTM A216 Materials Chemical

|

|||||||||||

| Grades | Iron (Fe) | Residuals | Manganese (Mn) | Silicon (Si) | Carbon (C) | Sulfur (S) | Phosphorus (P) | ||||

| Grade B | 97 to 100 % | 0 to 1.0 % | 0 to 1 % | 0 to 0.6 % | 1 to 0.3 % | 0 to 0.045 % | 0 to 0.04 % | ||||

Mechanical Properties Charts Of ASTM A216 Grade WCB

| Mechanical Properties | |||

| Mechanical Properties | ASTM A216 Grade WCB Cast Steel | ||

| Density: | 7.82 g/cm3 (488 lb/ft3) | ||

| Elastic (Young’s, Tensile) Modulus: | 210 GPa (30 x 106 psi) | ||

| Elongation at Break: | 25 % | ||

| Specific Heat Capacity: | 450 J/kg-K | ||

| Strength to Weight Ratio: | 73 kN-m/kg | ||

| Tensile Strength: Ultimate (UTS): | 570 MPa (83 x 103 psi) | ||

| Tensile Strength | 280 MPa (41 x 103 psi) | ||

| Thermal Expansion: | 11.9 µm/m-K | ||

Wow, superb blog layout!

How long have you ever been running a blog for?

you make running a blog look easy. The entire look of your web

site is fantastic, let alone the content material!

You can read similar here prev

next and it’s was wrote by Brenton76.

Wow, marvelous weblog layout!

How lengthy have you ever been blogging for? you make running a blog glance easy.

The overall glance of your web site is excellent, let alone the content!

I saw similar here prev next and those was wrote by

King73.

Wow, fantastic weblog structure!

How lengthy have you been running a blog for? you make blogging glance easy.

The full glance of your site is fantastic, as neatly as the content!

You can read similar here prev next and those was wrote

by Sherman87.

Wow, incredible weblog structure!

How lengthy have you ever been blogging for? you

made running a blog look easy. The whole look of your website is excellent, as well as the content!

You can read similar here Kellye Byg4.

2024/04/23

of course like your website however you have to take a look at the

spelling on quite a few of your posts. Many

of them are rife with spelling issues and I in finding it very bothersome

to tell the truth then again I will definitely come back

again.

Aw, this was an incredibly good post. Spending some time and actual effort to produce a great article… but what

can I say… I procrastinate a lot and never seem to get nearly anything done.

I visited several blogs except the audio feature for

audio songs current at this site is genuinely

fabulous.

After looking into a few of the blog posts on your website, I honestly like your technique of blogging.

I bookmarked it to my bookmark webpage list and will be checking back in the near future.

Please visit my web site as well and let me know your opinion.

I pay a quick visit daily a few blogs and sites

to read posts, but this web site presents quality based

articles.

Hi there i am kavin, its my first occasion to commenting anywhere, when i

read this post i thought i could also create comment due to this good piece of writing.

I constantly spent my half an hour to read this weblog’s articles

everyday along with a mug of coffee.

Greetings! Very helpful advice within this post! It’s the little changes which will make the greatest changes.

Many thanks for sharing!

Good day! I could have sworn I’ve been to your blog before but after going through a few of the posts I

realized it’s new to me. Regardless, I’m certainly happy I came across it and I’ll be book-marking it and checking back regularly!

I am not rattling superb with English but I get hold this rattling easygoing to interpret.

Hello, I wish for to subscribe for this web site to get hottest

updates, therefore where can i do it please assist.

Our premium databases recompense XRumer and GSA Search Engine Ranker are just what you need!

What do our databases include?

• Running links: Get access to constantly updated lists of physical links from profiles, posts, forums, guestbooks, blogs, and more. No more wasting time on unbroken links!

• Verified and identified links: Our premium databases for GSA Search Engine Ranker include verified and identified links, categorized sooner than search engines. This means you pull down the highest quality links that desire help you row higher.

• Monthly updates: All of our databases are updated monthly to assure you have in the offing the most original and competent links.

Choose the perfect way out in the service of you:

• XRumer premium database:

o Premium database with at liberty updates: $119

o Premium database without updates: $38

• Fresh XRumer Database:

o Fresh database with free updates: $94

o Keen database without updates: $25

• GSA Search Mechanism Ranker Verified Links:

o GSA Search Engine Ranker activation tone: $65 (includes database)

o Green database with unconstrained updates: $119

o Untested database without updates: $38

Don’t waste for the moment on outdated or tranquil links. Swear in in our premium databases and start seeing results today!

Serenity now!

P.S. By purchasing GSA Search Locomotive Ranker from us, you become a high-quality product at a competitive price. Liberate your resources and start improving your SEO rankings today!

To friend us, get off to telegram https://t.me/DropDeadStudio promocode “DD50%”

Informative Site… Hello guys here are some links that contains information that you may find useful yourselves. It’s Worth Checking out 급전

I’m bookmarking this for future reference.급전