Centrifugal Pump Introduction

Centrifugal pumps are Important rotating equipment for oil and gas to water treatment, chemical processing, and many other industries. However, like other equipment, centrifugal pumps can also have some operational issues. To Identifying these issues early and implementing the right solutions can prevent costly downtime, improve efficiency, and extend the pump’s lifespan. This comprehensive troubleshooting guide covers common centrifugal pump problems, their causes, and the steps you can take to address them effectively.

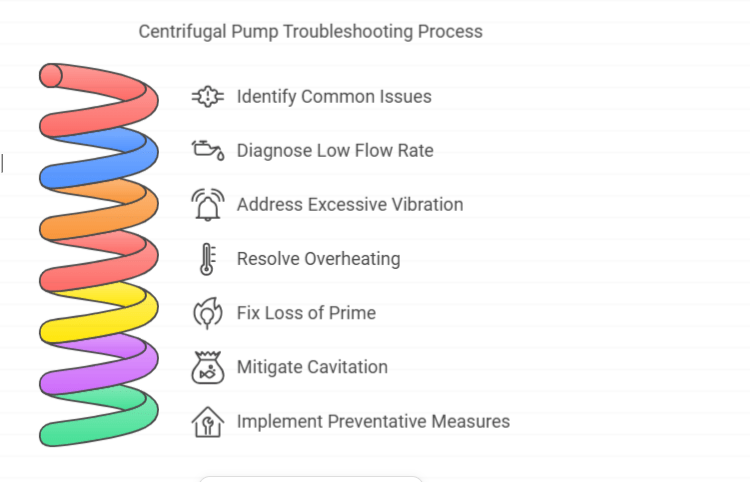

Table of Contents of this Articles

- Common Issues with Centrifugal Pumps

- Detailed Troubleshooting Guide

- Low Flow Rate

- Excessive Vibration

- Overheating

- Loss of Prime

- Cavitation

- Preventative Measures for Optimal Pump Performance

- Final Thoughts

Common Issues with Centrifugal Pumps

Centrifugal pumps can face numerous issues, often due to environmental factors, operating conditions, or component wear. Here are some common problems that operators encounter:

- Overheating: This can be caused by restricted flow or excessive load.

- Loss of Prime: Air enters the pump, preventing it from creating suction.

- Cavitation: Formation of vapor bubbles that can damage the pump impeller.

- Low or Reduced Flow Rate: The pump isn’t delivering the required amount of liquid.

- Excessive Vibration or Noise: The pump is shaking or creating unusual sounds, indicating possible misalignment or cavitation..

Each of these issues can stem from multiple root causes. Let’s dive into a step-by-step troubleshooting guide to identify and address each of these common problems.

Detailed Troubleshooting Guide

Low Flow Rate

A low flow rate is one of the most frequent complaints with centrifugal pumps. Here’s how to troubleshoot it:

- Check for Blockages: Inspect the suction and discharge lines for obstructions. Debris can restrict flow, reducing performance.

- Inspect Pump Impeller: Wear on the impeller or clogging from sediment can impact flow rate. Regular maintenance and inspection can prevent this.

- Verify Suction Conditions: Ensure the suction pipe is adequately sized, without air leaks, and that the Net Positive Suction Head (NPSH) is maintained to avoid cavitation.

Excessive Vibration and Noise

Excessive vibration can shorten the lifespan of the pump and related equipment. Possible causes and solutions include:

- Misalignment: Misaligned pumps can cause vibrations. Ensure proper alignment during installation and check it periodically.

- Worn Bearings: Bearings that are worn out or improperly lubricated can lead to vibration. Regular bearing maintenance and lubrication checks are essential.

- Cavitation: When vapor bubbles form and collapse near the impeller, they create a rattling noise and vibration. Adjusting flow rates or suction pressure can reduce cavitation.

Overheating

Overheating in centrifugal pumps is often due to flow restrictions or mechanical issues. Here’s how to troubleshoot it:

- Check Flow Rate: If the pump operates with too little flow, it can overheat. Verify that the pump isn’t being “deadheaded” (running without flow).

- Inspect Lubrication: Improper or insufficient lubrication of bearings can increase friction, causing heat. Ensure that lubricants are of the right type and quantity.

- Review Cooling Systems: Some pumps have dedicated cooling systems. Ensure all components are functional, and there’s no blockage in the cooling lines.

Loss of Prime

Loss of prime can prevent the pump from generating the necessary suction. Here’s how to address it:

- Inspect for Air Leaks: Check the suction line and pump casing for any leaks that could introduce air.

- Check Foot Valves and Strainers: A damaged or leaking foot valve can lead to loss of prime. Ensure the foot valve and strainer are intact and functioning.

- Properly Prime the Pump: When starting, make sure the pump casing is fully primed. This step prevents air from being trapped inside, which could disrupt suction.

Cavitation

Cavitation can cause severe damage to the pump’s internal parts. It typically occurs due to low pressure at the pump’s inlet. To troubleshoot cavitation:

- Increase NPSH: Ensure adequate NPSH at the pump inlet. This may involve adjusting the suction line or changing the pump location.

- Reduce Pump Speed: Operating at lower speeds can minimize cavitation, especially in high-temperature applications.

- Maintain Proper Suction Conditions: Ensure that the suction line is clear and the fluid level is appropriate. Adding a pressure booster may help in low-pressure situations.

Preventative Measures for Optimal Pump Performance

Implementing preventative measures can significantly reduce the frequency of pump issues. Here are some best practices:

- Monitor Operating Conditions: Keep an eye on pressure, temperature, and flow rate to detect irregularities early.

- Lubrication and Cooling: Proper lubrication and cooling systems ensure components run smoothly, minimizing wear and tear.

- Train Staff: Proper training for personnel on correct operating and maintenance procedures can reduce errors that lead to equipment wear.

- Regular Inspections and Maintenance: Periodic checks on components like bearings, seals, impellers, and alignment can prevent unexpected issues.

Final Thoughts

Centrifugal pumps are essential assets in any industrial setting, and keeping them in optimal condition is key to maintaining productivity. By understanding common pump issues and implementing effective troubleshooting techniques, operators can minimize downtime and extend pump life. Remember, regular maintenance and monitoring are your best defenses against pump failure. Stay proactive, follow best practices, and ensure that your centrifugal pumps deliver reliable, consistent performance.