Gate valves: pros and cons

Gate valves are commonly used in industries where low fluid resistance and tight sealing are necessary. They operate by either completely opening or closing the gate inside the valve body to control the flow of fluids. One of the main advantages of gate valves is their ability to shut off flow completely, making them ideal for applications that require complete isolation. However, they have a slower operating time compared to other valve types, which can be a disadvantage in certain situations that require quick responses. Additionally, gate valves may suffer from wear and tear over time, causing leaks or even breakage that can lead to safety hazards if not properly maintained.

When it comes to controlling the flow of fluids in a pipeline or other industrial application, selecting the right type of valve can make all the difference in performance, efficiency, and cost-effectiveness. In this comparison guide, we’ll explore all popular options of valves.

Gate Valve vs Globe valve

Durability, maintenance, and cost considerations for both types of valves.

When selecting between gate valves and ball piston globe valves, durability, maintenance, and cost considerations are important factors to keep in mind. Gate valves are known for their durable construction and long service life, making them a popular choice for industrial applications. However, they can require more maintenance due to their design and may be more costly than other types of valves. Ball piston globe valves offer excellent durability with less required maintenance thanks to superior sealing capabilities. They can also be less expensive than gate valves in certain situations. Careful consideration of these factors will help you choose the best valve for your specific needs.

Flow Characteristics: Globe valves are designed to regulate flow, while gate valves are designed for on/off flow control. Globe valves have a more gradual opening and closing mechanism that allows for precise control of flow rate. Gate valves have a simple open/closed mechanism that allows for faster and more complete shutoff.

Pressure Drop: Globe valves have a higher pressure drop than gate valves because of their more restrictive flow path. This means that globe valves may require more energy to operate and can cause more wear on the valve components.

Size and Weight: Gate valves are generally larger and heavier than globe valves, especially in larger pipe sizes. This can make gate valves more difficult to install and maintain, but it also makes them more durable and resistant to damage.

Maintenance: Globe valves are generally easier to maintain than gate valves because they have fewer moving parts and are less likely to become clogged or obstructed. Gate valves may require more frequent maintenance to keep the gate mechanism functioning properly.

Applications: Globe valves are commonly used in applications that require precise flow control, such as in the chemical and pharmaceutical industries. Gate valves are often used in applications that require quick shutoff, such as in the oil and gas industry or in fire protection systems.

Overall, the choice between a gate valve and a globe valve will depend on the specific requirements of the application, including the desired flow rate, pressure, and maintenance requirements.

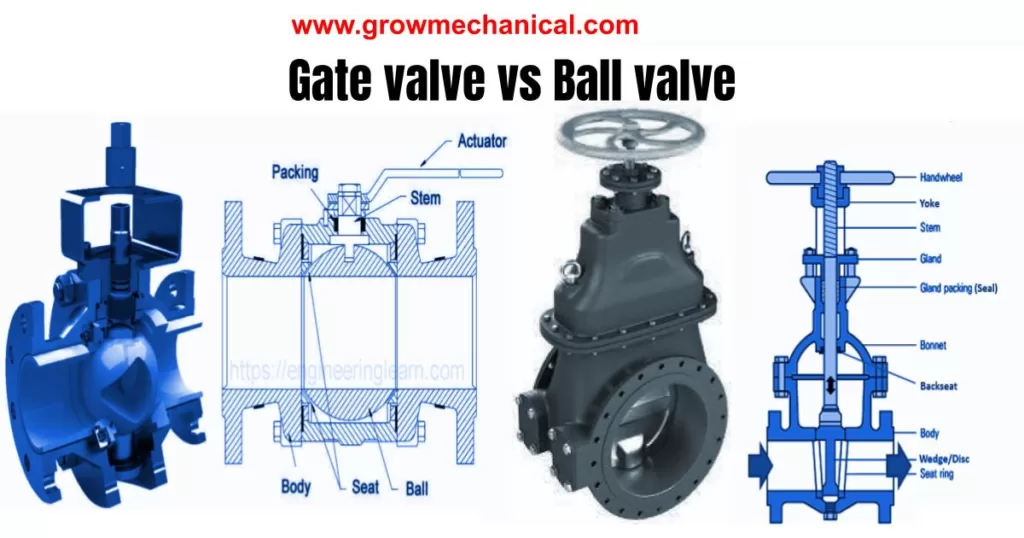

Gate valve vs ball valve

Gate valves and ball valves are both types of quarter-turn valves commonly used in industrial applications, but they differ in several key ways:

- Flow Characteristics: Ball valves have a more unrestricted flow path than gate valves, allowing for higher flow rates and lower pressure drops. Gate valves have a more restrictive flow path and are designed for on/off flow control rather than precise flow regulation.

- Operation: Ball valves have a simple quarter-turn operation that makes them easy to operate and control. Gate valves require multiple turns to fully open or close, which can make them slower to operate and less precise in regulating flow.

- Maintenance: Ball valves are generally easier to maintain than gate valves because they have fewer moving parts and are less likely to become clogged or obstructed. Gate valves may require more frequent maintenance to keep the gate mechanism functioning properly.

- Cost: Ball valves are generally less expensive than gate valves, especially in smaller sizes. However, for larger sizes or higher-pressure applications, gate valves may be more cost-effective due to their durability and resistance to wear.

- Applications: Ball valves are commonly used in applications that require quick shutoff and low-pressure drop, such as in the oil and gas industry or in HVAC systems. Gate valves are often used in applications that require high-pressure drop and/or precise flow control, such as in the chemical and pharmaceutical industries.

- Overall, the choice between a gate valve and a ball valve will depend on the specific requirements of the application, including the desired flow rate, pressure, maintenance requirements, and budget.

Gate valve vs piston valve

Gate valves and piston valves are both types of valves used for controlling fluid flow, but they differ in several key ways:

- Design: Gate valves use a sliding gate mechanism to control flow, while piston valves use a piston that moves back and forth to regulate flow.

- Flow Characteristics: Gate valves have a more restrictive flow path than piston valves, which can result in higher pressure drops and slower flow rates. Piston valves have a more open flow path and are designed for high flow rates.

- Maintenance: Gate valves are generally easier to maintain than piston valves because they have fewer moving parts and are less prone to wear and tear. Piston valves require more frequent maintenance to keep the piston mechanism functioning properly.

- Cost: Gate valves are generally less expensive than piston valves, especially in smaller sizes. However, for larger sizes or higher-pressure applications, piston valves may be more cost-effective due to their durability and resistance to wear.

- Applications: Gate valves are often used in applications that require quick shutoff and/or precise flow control, such as in the oil and gas industry or in fire protection systems. Piston valves are commonly used in applications that require high flow rates, such as in water treatment or power generation.

- Overall, the choice between a gate valve and a piston valve will depend on the specific requirements of the application, including the desired flow rate, pressure, maintenance requirements, and budget.

Gate valve vs butterfly valve

Gate valves and butterfly valves are both types of quarter-turn valves used for regulating fluid flow, but they differ in several key ways:

- Design: Gate valves use a sliding gate mechanism to control flow, while butterfly valves use a rotating disc to regulate flow.

- Flow Characteristics: Butterfly valves have a more unrestricted flow path than gate valves, allowing for higher flow rates and lower pressure drops. Gate valves have a more restrictive flow path and are designed for on/off flow control rather than precise flow regulation.

- Operation: Butterfly valves have a simple quarter-turn operation that makes them easy to operate and control. Gate valves require multiple turns to fully open or close, which can make them slower to operate and less precise in regulating flow.

- Maintenance: Butterfly valves are generally easier to maintain than gate valves because they have fewer moving parts and are less likely to become clogged or obstructed. Gate valves may require more frequent maintenance to keep the gate mechanism functioning properly.

- Applications: Butterfly valves are commonly used in applications that require quick shutoff and/or low-pressure drop, such as in the food and beverage industry or in HVAC systems. Gate valves are often used in applications that require high-pressure drop and/or precise flow control, such as in the chemical and pharmaceutical industries.

- Overall, the choice between a gate valve and a butterfly valve will depend on the specific requirements of the application, including the desired flow rate, pressure, maintenance requirements, and budget.

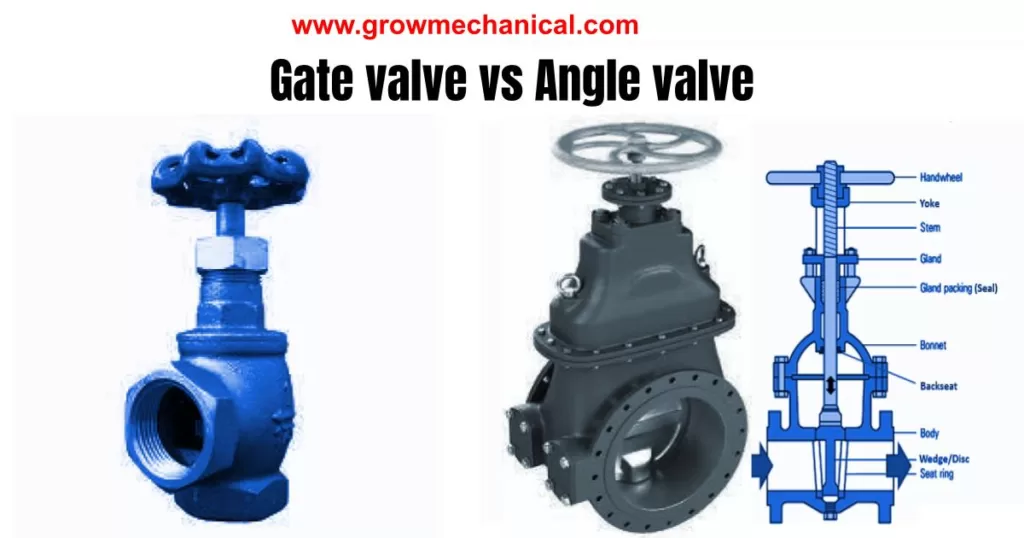

Gate valve vs angle valve

Gate valves and angle valves are both types of valves used for controlling fluid flow, but they differ in several key ways:

- Design: Gate valves use a sliding gate mechanism to control flow, while angle valves use a 90-degree bend in the valve body to change the direction of flow.

- Flow Characteristics: Gate valves have a more restrictive flow path than angle valves, which can result in higher pressure drops and slower flow rates. Angle valves have a more open flow path and are designed for high flow rates.

- Operation: Gate valves require multiple turns to fully open or close, which can make them slower to operate than angle valves. Angle valves have a simple quarter-turn operation that makes them easy to operate and control.

- Maintenance: Gate valves are generally easier to maintain than angle valves because they have fewer moving parts and are less prone to wear and tear. Angle valves require more frequent maintenance to keep the valve mechanism functioning properly.

- Applications: Gate valves are often used in applications that require high-pressure drop and/or precise flow control, such as in the chemical and pharmaceutical industries or in fire protection systems. Angle valves are commonly used in applications that require changes in flow direction, such as in plumbing or HVAC systems.

- Overall, the choice between a gate valve and an angle valve will depend on the specific requirements of the application, including the desired flow rate, pressure, maintenance requirements, and budget.

Gate valve vs needle valve

Gate valves and needle valves are both types of valves used for controlling fluid flow, but they differ in several key ways:

- Design: Gate valves use a sliding gate mechanism to control flow, while needle valves use a tapered needle-shaped plunger to regulate flow.

- Flow Characteristics: Needle valves have a very precise flow control, with the ability to make very small adjustments to flow rates. Gate valves, on the other hand, have a more restrictive flow path and are designed for on/off flow control rather than precise flow regulation.

- Operation: Needle valves have a threaded stem that can be turned to adjust the flow rate, making them easy to control. Gate valves require multiple turns to fully open or close, which can make them slower to operate.

- Maintenance: Needle valves have a relatively simple design with few moving parts, making them easy to maintain. Gate valves may require more frequent maintenance to keep the gate mechanism functioning properly.

- Applications: Needle valves are commonly used in applications that require very precise flow control, such as in laboratory settings or in instrumentation systems. Gate valves are often used in applications that require high-pressure drop and/or quick shutoff, such as in the oil and gas industry or in fire protection systems.

- Overall, the choice between a gate valve and a needle valve will depend on the specific requirements of the application, including the desired flow rate, pressure, precision, maintenance requirements, and budget.

- Gate Valves selection application and design

- Basic application of gate valve part 1

- Gate Valve Operation: Selection and Material