olyethylene vs. Polycarbonate: A Comparative Analysis of Strength and Properties

Engineers and designers often face the challenge of choosing between polyethylene (PE) and polycarbonate (PC) for their projects. Both are versatile thermoplastics, but their distinct properties make them suitable for different applications. Shenzhen Tuofa CNC Machining breaks down the key differences, with a focus on strength, to help you make an informed decision.

Understanding Polyethylene (PE)

PE is the world’s most common plastic, renowned for its affordability, flexibility, and chemical resistance. It’s a versatile material used in diverse applications, from packaging to construction.

Types of Polyethylene

- LDPE (Low-Density Polyethylene): Flexible, lightweight, and often used in films and bags.

- HDPE (High-Density Polyethylene): Stronger and stiffer than LDPE, used in bottles, pipes, and containers.

- UHMWPE (Ultra-High Molecular Weight Polyethylene): Exceptionally tough and wear-resistant, used in industrial applications like gears and bearings.

Key Strength Properties of PE

| Property | Typical Values (HDPE) |

| Tensile Strength (MPa) | 26-38 |

| Yield Strength (MPa) | 20-30 |

| Flexural Strength (MPa) | 1170-2340 |

| Impact Strength (J/m) | 50-90 (Notched Izod) |

PE, particularly HDPE, offers decent tensile and remarkable flexural strength due to its semi-crystalline structure. However, its impact strength is relatively lower compared to PC.

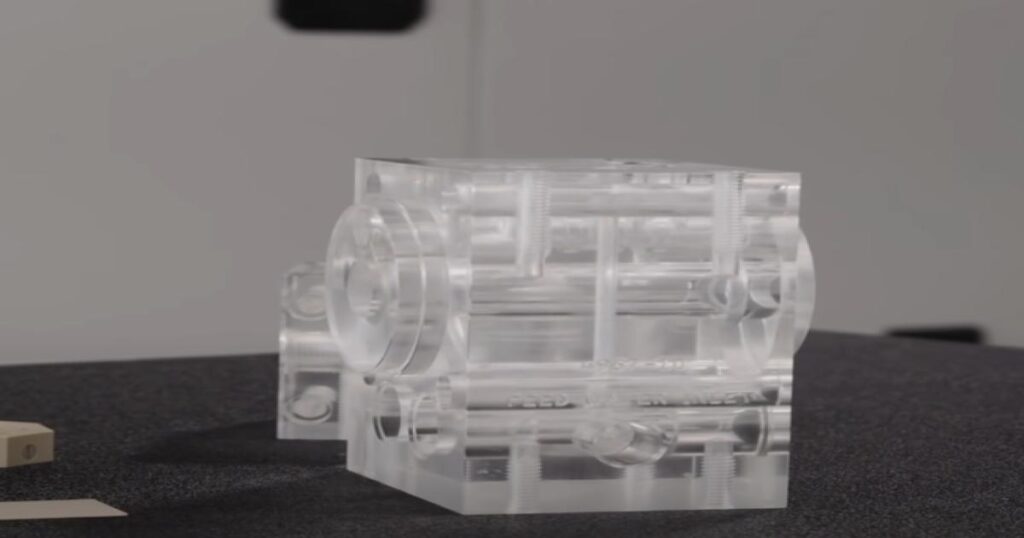

Understanding Polycarbonate (PC)

PC is a high-performance engineering thermoplastic known for its exceptional impact resistance, transparency, and heat resistance. It’s a popular choice for demanding applications where durability and optical clarity are paramount.

Need precision CNC machining for your polyethylene or polycarbonate project? Get a free, no-obligation quote from Tuofa CNC Machining today! Our expert team will work with you to understand your specific requirements and deliver high-quality parts that meet your exact specifications. Contact us today for get a free machining quote.

Key Strength Properties of PC

| Property | Typical Values |

| Tensile Strength (MPa) | 62-72 |

| Yield Strength (MPa) | 62 |

| Flexural Strength (MPa) | 95-120 |

| Impact Strength (J/m) | 850-900 (Notched Izod) |

PC boasts high tensile and flexural strength, but its standout feature is its exceptional impact resistance, making it virtually unbreakable under normal conditions.

Direct Strength Comparison: PE vs. PC

| Property | Polyethylene (HDPE) | Polycarbonate (PC) | Winner |

| Tensile Strength | Moderate | High | PC |

| Yield Strength | High | Moderate | PE |

| Impact Strength | Low | Extremely High | PC |

While PE, particularly HDPE, demonstrates higher yield strength, PC is the clear winner in tensile and impact strength.

Chemical Resistance: Which Material Stands Up to the Test?

| Chemical | Polyethylene (HDPE) | Polycarbonate (PC) |

| Acids | Excellent | Poor |

| Bases | Excellent | Poor |

| Alcohols | Excellent | Fair |

| Ketones | Good | Poor |

| Hydrocarbons | Excellent | Poor |

PE exhibits superior chemical resistance across a wider range of substances compared to PC.

Thermal Properties: Handling the Heat

| Property | Polyethylene (HDPE) | Polycarbonate (PC) |

| Melting Point (°C) | 130-137 | 220-250 |

| Heat Deflection Temperature (°C) (at 66 psi) | 45-60 | 130-140 |

PC demonstrates significantly higher heat resistance than PE, making it suitable for applications exposed to elevated temperatures.

Optical Properties: Clarity vs. Opacity

- PC: Highly transparent, ideal for lenses, safety glasses, and displays.

- PE: Translucent to opaque, unsuitable for optical applications.

Machinability and Processing: CNC Machining Considerations

Both PE and PC are machinable using CNC technology. However, their distinct properties require different approaches:

- PE: Requires sharp tools and lower cutting speeds to prevent melting.

- PC: Allows for higher cutting speeds and a wider range of tooling options.

Tuofa CNC Machining has extensive experience in machining both PE and PC, ensuring precise and high-quality results for your projects.

Choosing the Right Material: A Decision-Making Framework

Consider these factors when deciding between PE and PC:

- Strength Requirements: PC for high impact resistance, PE for specific yield strength needs.

- Chemical Exposure: PE for superior chemical resistance.

- Temperature: PC for high-temperature environments.

- Optical Clarity: PC for transparent applications.

- Budget: PE is generally more cost-effective.

Conclusion: Making the Right Choice

Understanding the strengths and weaknesses of both polyethylene and polycarbonate is crucial for selecting the right material for your project. By carefully considering your specific requirements and consulting with experts like Tuofa CNC Machining, you can confidently choose the material that will best meet your needs and ensure the success of your product.