Side Stream Filters: Improve Water Quality For Cooling Tower

Are you looking for an effective solution to improve the water quality in your cooling tower? Side stream filters might be the answer you’ve been searching for. That have ability to remove debris, contaminants, and sediment from the water, side stream filters play a crucial role in maintaining the cleanliness and efficiency of cooling tower systems.

These filters work by diverting a small portion of the water flow from the cooling tower system, passing it through a filter media with the help op pump, and then returning it back to the system. By continuously removing impurities from the water, side stream filters help to reduce the risk of fouling, corrosion, and scale formation, ultimately improving the overall water quality and system performance of cooling towers.

Side stream filter can use for filtration of the following sizes of impurities Particle Sand – 100 to 2,000 Microns, Pollens – 10 to 1,000 Microns, Mold Spores10 to 30 Microns, and Bacteria likes 3 Microns.

Importance of water quality in cooling towers

Water quality is a critical factor that directly affects the performance and lifespan of cooling towers. Cooling towers are used in various industries to remove excess heat from industrial processes or HVAC systems. The primary function of a cooling tower is to transfer heat from the system to the atmosphere through evaporation. During this process, water is continuously circulated, making it prone to contamination and impurities.

Poor water quality in cooling towers can lead to several issues. like, it can result in fouling, which occurs when impurities accumulate on heat exchange surfaces. This buildup reduces the efficiency of heat transfer, resulting in higher energy consumption and decreased cooling capacity. Moreover, fouling can lead to an increase in the system’s pressure drop, requiring more energy to maintain the desired flow rate.

Secondly, inadequate water quality can cause corrosion within the cooling tower system. Corrosion can damage vital components like pipes, valves, and heat exchangers, leading to leaks, system failure, and costly repairs. Additionally, corrosion products can contaminate the water, further exacerbating the fouling issues mentioned earlier.

Lastly, scale formation is another common problem associated with poor water quality. When water evaporates, minerals and other dissolved solids can precipitate and form scale deposits on heat exchange surfaces. Scale reduces heat transfer efficiency, increases pressure drop, and promotes microbial growth. These issues can significantly impact the overall performance and lifespan of cooling towers.

Common issues with cooling tower water

Side stream filters are designed to continuously remove impurities from the water circulating in the cooling tower system. They work by diverting a small portion of the water flow from the main system and passing it through a filter media. The filter media can vary depending on the specific requirements, but commonly used ones include sand, multimedia, and cartridge filters.

As the water flows through the filter media, debris, contaminants, and sediment are trapped, leaving behind cleaner water. The filtered water is then returned to the cooling tower system, contributing to improved water quality and reducing the risk of fouling, corrosion, and scale formation.

Side stream filters operate on a continuous basis, ensuring that the water remains clean and free from impurities. By removing particulate matter, organic material, and other contaminants, these filters help maintain optimal system performance and prolong the lifespan of equipment.

How side stream filters work

The use of side stream filters in cooling towers offers numerous benefits. Firstly, they significantly improve water quality by removing impurities that can cause fouling, corrosion, and scale formation. Cleaner water translates to better heat transfer efficiency, reduced energy consumption, and improved cooling tower performance.

Secondly, side stream filters help extend the lifespan of equipment. By preventing the accumulation of debris and contaminants, they reduce the wear and tear on crucial components like pumps, valves, and heat exchangers. This leads to fewer breakdowns, less downtime, and lower maintenance and operational costs.

Another advantage of side stream filters is their ability to minimize water treatment chemical usage. With cleaner water, the need for chemicals such as biocides, scale inhibitors, and corrosion inhibitors is reduced. This not only saves costs but also reduces the environmental impact associated with chemical usage.

Additionally, side stream filters contribute to a safer working environment. By removing organic matter, bacteria, and other potential health hazards, they help maintain better air quality around the cooling tower. This is particularly important in industries where employees are in close proximity to the cooling tower system.

Benefits of using side stream filters in cooling towers

When selecting a side stream filter for your cooling tower system, several factors should be taken into consideration. The first factor is the flow rate and capacity. It is essential to choose a filter that can handle the required flow rate of your cooling tower system. Additionally, consider the size and footprint of the filter, ensuring it can be easily integrated into your existing setup.

The second factor to consider is the type of filter media. Different filter media have varying levels of filtration efficiency and capacity. The choice of filter media should align with your specific water quality requirements and the type of contaminants typically found in your cooling tower system.

Another crucial factor is the maintenance requirements of the side stream filter. Opt for a filter that is easy to clean, maintain, and replace. Regular maintenance is essential to ensure optimum performance and longevity of the filter. Consider filters that come with automated cleaning mechanisms or easy-to-access filter media for efficient maintenance.

Lastly, consider the overall cost-effectiveness of the filter. Evaluate the initial investment, ongoing maintenance costs, and potential energy savings that can be achieved by using the filter. While it’s important to choose a high-quality filter, it should also provide a reasonable return on investment over its lifespan.

Factors to consider when choosing a side stream filter

The installation of a side stream filter should be done by qualified professionals who understand the specific requirements of your cooling tower system. Proper installation ensures optimal performance and avoids any potential issues that may arise from incorrect setup. This includes proper sizing, positioning, and connection to the cooling tower system.

Regular maintenance is crucial to ensure the continued effectiveness of the side stream filter. Cleaning and replacing the filter media, inspecting valves, and monitoring pressure differentials are some of the maintenance tasks that should be performed at regular intervals. It’s important to follow the manufacturer’s guidelines and recommendations for maintenance to ensure the longevity and performance of the filter.

Installation benfits of side stream filters

After installing a side stream filter, they noticed a significant reduction in fouling and improved heat transfer efficiency. This led to energy savings of 20% and a substantial decrease in maintenance costs. By integrating a side stream filter, they were able to remove these contaminants, resulting in improved air quality and a healthier environment for patients, staff, and visitors. After installing a side stream filter and implementing a proper water treatment program, corrosion was significantly reduced, resulting in a longer lifespan for their equipment and substantial cost savings.

These case studies highlight the positive impact that side stream filters can have on the overall performance, efficiency, and cost-effectiveness of cooling towers.

Case studies of successful side stream filter implementation

Water quality in cooling towers is subject to various industry regulations and standards. These regulations aim to ensure the safety of cooling tower operation, protect the environment, and prevent the spread of waterborne diseases. The Occupational Safety and Health Administration (OSHA) also provides guidelines for the management of cooling tower systems to ensure worker safety. which focuses on the prevention of Legionella bacteria growth in building water systems, including cooling towers. Implementing side stream filters can contribute to meeting these requirements by improving water quality and reducing the risk of bacterial growth and other waterborne contaminants.

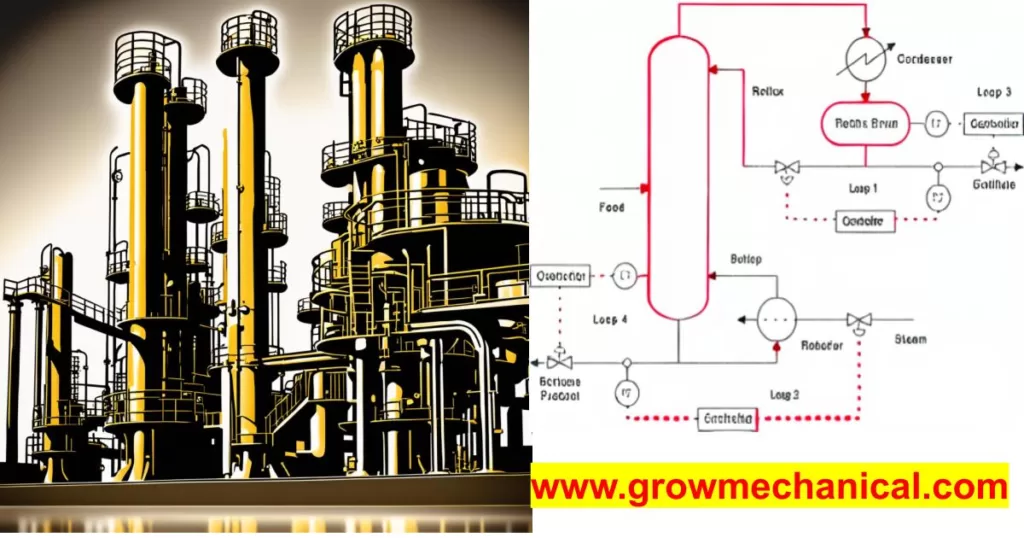

Types of equipment used with cooling towers

Some common type of equipment used in the system with cooling tower, these are following. As shown above-mentioned pictures.

- Side stream filter

- cooling tower pump

- A heat exchanger (Metallic)

- Water sump (RCC)

- Chamical dosing system

- Fan deck (FRC)

- Motors With cooling tower fan (Aluminium or FRC)

- Basin (RCC)

Types of side stream filter or filter

There are mainly five types of filters used as a side stream filtration system, their name with filtration capacity are mentioned below.

- Plastic Disk Filter (Less than or equal to 10 microns)

- Pressure Sand Filter (Less than or equal to 10 microns)

- Automatic Screen Filter (Less than or equal to 10 microns)

- Centrifugal Separators (40-75 microns, fine to coarse inorganics with a specific gravity of 1.62 or greater )

- High-Efficiency Sand Filter (Less than or equal to 0.45 microns) Best for fine, light particles; avoid heavy coarse particle applications

How to select side stream filter on the base of technical spacification

Selection side stream filter

The following technical data required to select appropriate side stream filter for your application, these are

- Flow rate

- Backwash duration

- filter size selection

- nos. of stages or module

- Min and max Backwash pressure

- Backwash flow rate and backwash system type

- Inlet and outlet nozzle size for connection

- Min and max working pressure and temperature of your application.

Material selection for side stream filter

There are mentioned most common type of material use in side stream filter for cooling water application.

- filter housing casing and lid – (Rainforced polypropylene, RPP)

- Small bore tubing – PA AND PE

- Seals – ptfe nbr an viton

- Associate mainifolds – PP

- Inlet valve – RPP

Why side stream filter used and its benefits

Side stream filter is the best and appropriate filtration tool to save equipment from fouling and deposition in a cooling water system.

This type of filter can improve your system life in the way you like.

- Increased chemical efficiency

- Reduced the corrosion rates of equipment and piping system.

- Reduced maintenance costs are due to reduce deposition and fouling.

- Decreased chemical biocide, use because side stream filters work efficiently.

- Increased the equipment life by improving the water quality and kill the bacteria.

- Better system efficiency because reduce the deposition chance and increase the heat reduction rate.

Where is the side stream filter used?

Many reasons are present to select side stream filter, following the most popular scenario mentioned for used SS Filter.

- Frequently maintenance activity has to do without a schedule.

- solid particle showing in large amount, solid particle buildup is fast.

- The heat transfer rate is reduced due to deposition rather than corrosion.

- Facing Biological problems in past experience and chance to present in the new system as well.

- Heat exchanger, condenser, and other equipment internal part showing fouling even though the best anti foulant system is present in the existing system.

- cooling water (Makeup) source is a river, sewage, and other (unclarified water) it means that highly suspended solids and other unwanted impurity are chance to present.

You can visit our article by following below given post