The Ultimate Guide to Cooling Towers

Cooling towers play a crucial role in maintaining optimal temperatures for a wide range of industrial processes, power plants, and HVAC systems. Throughout this guide, we will cover workings of cooling towers, their types, components, operation, and maintenance.

Also discuss different types of cooling towers, including cross flow, counterflow, and hybrid designs. You’ll learn how these towers harness the power of evaporation and air circulation to efficiently control temperatures and cool water.

Furthermore, we will emphasize the critical importance of proper maintenance and the potential issues that can arise when cooling towers are not cared for correctly. From water treatment and cleaning procedures to regular inspections and necessary repairs, we will provide you with practical tips to ensure your cooling tower remains in peak condition.

How Cooling Towers Work and Key Components

Cooling towers are essential components in various industrial processes, HVAC systems, and power plants. They play a crucial role in removing excess heat and maintaining optimal operating temperatures.

Cooling towers are heat rejection devices that remove heat from a process or building environment by transferring it to the atmosphere. The primary mechanism behind their operation is the process of evaporation, convection, and radiation.

Heat Absorption

Cooling towers receive hot water or fluid from the industrial process, such as a power plant or manufacturing facility. This hot water contains excess heat that needs to be dissipated to prevent equipment overheating.

Water Distribution

The hot water is distributed evenly over the fill material inside the cooling tower. This fill material is designed to maximize the water’s exposure to air, facilitating the cooling process.

Air Circulation

Cooling towers use fans or natural airflow to draw air into the tower. As the hot water flows over the fill material, a portion of it evaporates into the surrounding air. This phase change from liquid to vapor absorbs a significant amount of heat.

Heat Dissipation

As the water loses heat through evaporation, it becomes cooler. The cooled water collects at the bottom of the tower and is returned to the industrial process or equipment for further cooling. This cycle repeats continuously, maintaining the desired temperature.

Components of Cooling Towers

To better understand how cooling towers work, let’s explore the key components that contribute to their functionality.

Fill Material

Fill material is a critical component inside the cooling tower. It consists of a network of sheets or tubes designed to increase the surface area for water exposure to the airflow, facilitating efficient heat exchange.

Fans

Fans are used to circulate air through the cooling tower. They play a pivotal role in enhancing the rate of evaporation and, consequently, the cooling efficiency.

Water Basin

The water basin collects the cooled water after it has gone through the fill material. It ensures a constant supply of cooled water for recirculation.

Drift Eliminators

Drift eliminators prevent water droplets from being carried out of the cooling tower along with the air. This helps in conserving water and maintaining environmental compliance.

Pump

A pump is responsible for circulating water from the basin back into the industrial process or equipment. It maintains a continuous flow of cooling water.

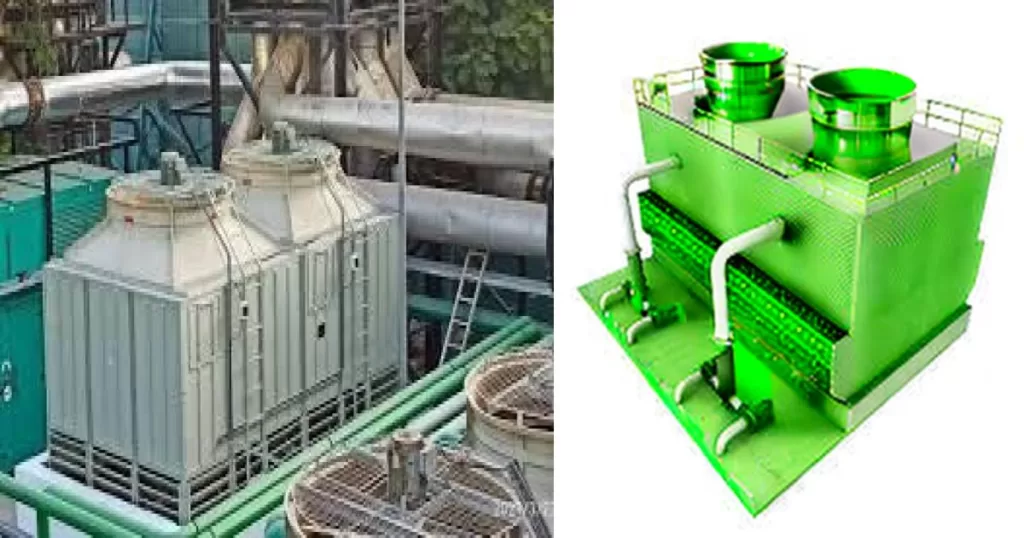

Types of cooling towers

Cooling towers play a crucial role in industrial processes by dissipating heat generated during various operations. They are essential components in maintaining optimal operating conditions for equipment and machinery. In this guide, we will explore the different types of cooling towers used across industries and highlight their key characteristics.

Natural Draft Cooling Towers

Natural draft cooling towers are massive structures often seen at power plants and industrial facilities. They rely on the principle of natural convection for cooling.

Key Features:

- No Fans: Natural draft towers do not require mechanical fans for air circulation.

- Tall Structures: They are typically very tall to create the necessary draft effect.

- High Efficiency: These towers are highly efficient for large-scale heat dissipation.

Mechanical Draft Cooling Towers

Mechanical draft cooling towers are more common in commercial and industrial applications. They use fans to enhance the airflow through the tower.

Key Features:

- Fan-Assisted: Mechanical draft towers employ fans to increase air circulation.

- Versatility: They are adaptable to various industrial processes and sizes.

- Energy Consumption: Typically, they consume more energy compared to natural draft towers.

Crossflow Cooling Towers

Crossflow cooling towers are characterized by the perpendicular airflow of the air and water streams. This design offers several advantages.

Key Features:

- Efficient Heat Transfer: The crossflow design allows for efficient heat exchange.

- Compact Size: They are relatively compact, making them suitable for limited spaces.

- Easy Maintenance: Maintenance is generally more accessible due to their design.

Counterflow Cooling Towers

Counterflow cooling towers have an airflow pattern where air moves upward while water flows downward. This design provides its unique benefits.

Key Features:

- High Efficiency: Counterflow towers are known for their superior heat transfer efficiency.

- Space-Efficient: They require less ground space compared to crossflow towers.

- Maintenance Considerations: Maintenance can be more challenging due to the design complexity.

Induced Draft Cooling Towers

Induced draft cooling towers have fans placed at the top of the tower, creating negative pressure to draw air through the tower.

Key Features:

- Improved Airflow Control: Induced draft towers offer better control over airflow.

- Energy Efficiency: They are often more energy-efficient than forced draft towers.

- Less Susceptible to Weather: These towers are less affected by adverse weather conditions.

Forced Draft Cooling Towers

Forced draft cooling towers have fans located at the base of the tower, pushing air upwards through the tower.

Key Features:

- Uniform Air Distribution: Forced draft towers provide uniform airflow.

- Ease of Maintenance: Maintenance tasks are typically easier due to fan accessibility.

- Energy Consumption: They tend to consume more energy compared to induced draft towers.

Open Circuit Cooling Towers

Open circuit cooling towers allow direct contact between the process water and the atmosphere, facilitating heat transfer through evaporation.

Key Features:

- Water Efficiency: Effective for applications where water conservation is a priority.

- Susceptibility to Contamination: Open circuit towers are more susceptible to contamination.

Closed Circuit Cooling Towers

Closed circuit cooling towers maintain a closed loop system, where process water is separated from the external environment, reducing the risk of contamination.

Key Features:

- Contamination Control: Ideal for processes requiring water purity.

- Water Conservation: They are more water-efficient compared to open circuit towers.

6 Key Benefits of Utilizing Cooling Towers for Industrial Applications

Introduction: Cooling towers are vital components in various industrial processes, helping to manage the temperature of equipment and systems efficiently. In this listicle, we’ll explore six significant advantages of using cooling towers, demonstrating their value in maintaining optimal operating conditions.

Energy Efficiency: Cooling towers are highly energy-efficient cooling systems. They utilize the natural process of evaporation to dissipate excess heat, which is far more economical compared to conventional methods like air conditioning or refrigeration. This results in reduced energy consumption and lower operating costs.

Environmental Friendliness:

Cooling towers are environmentally friendly cooling solutions. By relying on the principle of evaporative cooling, they use less electricity and minimize the release of greenhouse gases into the atmosphere. This not only reduces your carbon footprint but also helps you comply with environmental regulations.

Improved Equipment Lifespan: Maintaining the appropriate operating temperature is crucial for extending the lifespan of industrial equipment. Cooling towers efficiently remove excess heat, preventing overheating and premature wear and tear. This translates to longer equipment life and fewer replacement costs.

Process Optimization:

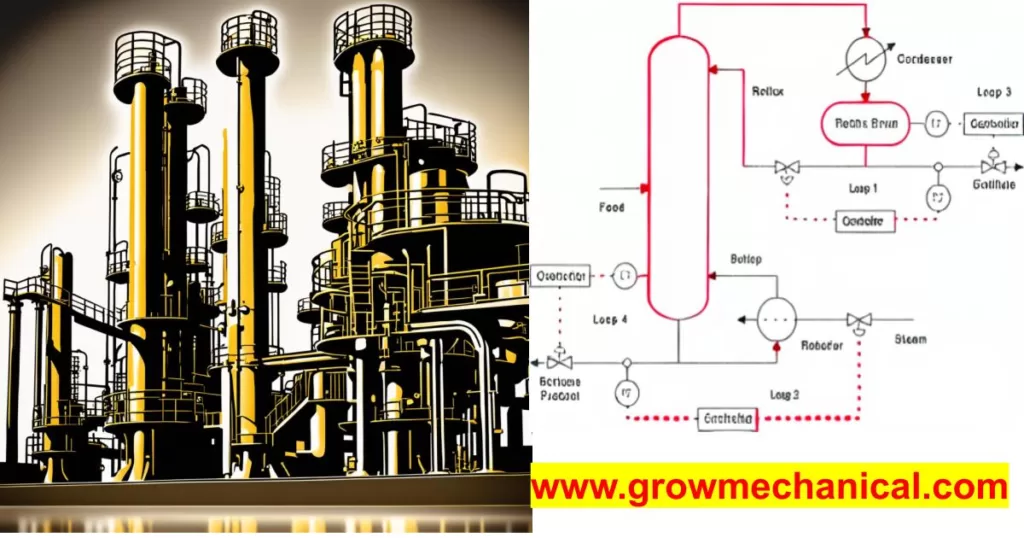

Cooling towers play a pivotal role in enhancing process efficiency. They enable consistent temperature control, ensuring that industrial processes run smoothly and produce high-quality output. This is particularly important in industries like manufacturing, power generation, and petrochemicals.

Water Conservation: Many cooling towers are designed to recycle and reuse water, reducing the overall water consumption in industrial facilities. This eco-friendly feature not only conserves a precious resource but also lowers water treatment costs.

Cost Savings:

Overall, cooling towers offer substantial cost savings for businesses. Their energy-efficient operation, extended equipment lifespan, reduced water consumption, and enhanced process efficiency contribute to a significant return on investment over time.

Maintenance and Troubleshooting Tips for Cooling Towers

To ensure their efficiency and longevity, regular maintenance and troubleshooting are essential. In this guide, we’ll provide you with important maintenance and troubleshooting tips for cooling towers, helping you optimize their performance and prevent costly downtime.

- Regular Inspection: Regular visual inspections are vital to identify potential issues early. Look for signs of corrosion, scale buildup, or leaks.

- Cleanliness Matters: Clean the cooling tower basin, fill, and drift eliminators regularly. Remove debris, sediment, and biological growth to maintain optimal heat transfer.

- Water Quality Control: Monitor and control the quality of water in the system. Implement water treatment programs to prevent scale, corrosion, and microbial growth.

- Lubrication: Keep fan motors, bearings, and other moving parts well-lubricated. This reduces friction and extends the lifespan of critical components.

- Fan Maintenance: Inspect fan blades for damage or imbalance. Ensure they are clean and properly aligned. Unbalanced fans can lead to vibration issues.

- Vibration Analysis: Regularly conduct vibration analysis on the motor, fan, and gearbox. High vibration levels may indicate misalignment or worn-out components.

- Motor and Drive Inspection: Check the condition of motors and drives. Loose connections or overheating can lead to motor failure and system shutdown.

- Water Treatment Systems: Monitor and maintain water treatment systems such as chemical dosing pumps and filtration units. Ensure they are functioning correctly.

- Temperature Control: Regularly check the temperature of the water entering and leaving the tower. Sudden temperature spikes could indicate a problem.

- Emergency Procedures: Develop and regularly review emergency procedures for cooling tower shutdowns and restarts to minimize risks during critical situations.

Troubleshooting:

In the event of cooling tower issues, follow these troubleshooting steps:

- Inspect Water Flow: Check for blockages or restrictions in water flow, which can lead to reduced cooling efficiency.

- Check for Leaks: Inspect the entire system for leaks, including pipes, valves, and the tower itself.

- Assess Temperature Fluctuations: Investigate sudden temperature changes, which can indicate issues with water circulation or heat exchange.

- Review Motor and Fan Performance: Analyze motor and fan performance data to identify irregularities or overloads.

- Monitor Water Chemistry: Test water samples for chemical imbalances, such as high mineral content or pH levels.

- Consult Manufacturer Guidelines: Refer to the manufacturer’s maintenance and troubleshooting guidelines for specific recommendations.

Cooling Towers: Essential Parameters and Formulas

To ensure their effectiveness, it’s essential to comprehend the key parameters and formulas governing their operation.

Approach Temperature (ΔT)

Formula: ΔT = T_inlet – T_outlet

Impact: A smaller ΔT indicates better cooling tower performance. It reflects how effectively the tower cools the water compared to the ambient air temperature. A lower ΔT results in more efficient cooling.

Cooling Range

Formula: Cooling Range = T_inlet – T_wet_bulb_temperature

Impact: The cooling range represents the maximum temperature difference between the water entering the tower and the wet bulb temperature of the air. A wider cooling range indicates better cooling tower efficiency.

Circulation Rate (Q)

Formula: Q = Flow rate of water (gallons per minute, GPM)

Impact: Proper circulation ensures that the cooling tower can handle the heat load effectively. An insufficient circulation rate can lead to reduced cooling efficiency and equipment overheating.

Evaporation Loss (E)

Formula: E = Q * (Cycles of Concentration – 1)

Impact: Evaporation loss is the water lost due to the cooling process. Higher evaporation losses can increase water consumption and operating costs.

Cycles of Concentration (COC)

Formula: COC = TDS (Total Dissolved Solids) in circulating water / TDS in makeup water

Impact: A higher COC indicates less water makeup is required, reducing water and chemical consumption. However, it can also lead to increased scaling and fouling risks.

Fan Power (P)

Formula: P = (Airflow rate * Fan static pressure) / Fan efficiency

Impact: Lower fan power consumption reduces operational costs and environmental impact. It’s crucial to optimize fan efficiency to achieve energy savings.

Formulas for Cooling Tower Efficiency

Cooling Tower Efficiency (η)

Formula: η = (T_inlet – T_outlet) / (T_inlet – T_wet_bulb_temperature)

Impact: Cooling tower efficiency quantifies how well the tower cools the water. A higher efficiency value indicates better performance.

Heat Rejection (Qr)

Formula: Qr = Q * ΔT * 500

Impact: Heat rejection quantifies the cooling tower’s ability to dissipate heat. A higher heat rejection rate is essential for effectively cooling processes and equipment.

Essential Formulas for Cooling Tower Design

Cooling towers are integral to many industries, and their design is a critical aspect of ensuring efficient heat dissipation. Here are seven essential formulas used in cooling tower design, along with practical examples to illustrate their application:

Heat Load (Q)

Formula: Q = Flow rate (GPM) × Specific Heat Capacity (BTU/lb°F) × Temperature Difference (ΔT, °F)

Example: If the flow rate is 100 GPM, specific heat capacity is 1 BTU/lb°F, and ΔT is 10°F, then Q = 100 × 1 × 10 = 1000 BTU/hr.

Cooling Tower Tons (TR)

Formula: TR = Q / 12,000

Example: Using the previous example with Q = 1000 BTU/hr, TR = 1000 / 12,000 = 0.0833 tons.

Wet Bulb Temperature (WBT)

Formula: WBT is typically measured using a psychrometric chart or a weather station.

Example: WBT can vary based on location and time of year, so use local data for accurate calculations.

Approach (ΔT_approach)

Formula: ΔT_approach = Temperature of water leaving the cooling tower (°F) – WBT (°F)

Example: If the leaving water temperature is 85°F and the WBT is 75°F, then ΔT_approach = 85 – 75 = 10°F.

Circulation Rate (Q)

Formula: Q = TR × 12,000 / ΔT_approach

Example: Using the previous values, Q = 0.0833 tons × 12,000 / 10°F = 100 GPM.

vaporation Loss (E)

Formula: E = Q × (Cycles of Concentration – 1)

Example: If the cycles of concentration are 3 and Q is 100 GPM, then E = 100 × (3 – 1) = 200 GPM.

Makeup Water Flow Rate

Formula: Makeup Water Flow Rate = Q + E

Example: With Q = 100 GPM and E = 200 GPM, the makeup water flow rate is 100 + 200 = 300 GPM.

These formulas are fundamental in cooling tower design, helping engineers and operators determine the heat load, required circulation rate, and makeup water flow rate. By applying these formulas correctly, you can ensure your cooling tower system is designed to efficiently dissipate heat while minimizing water and energy consumption.