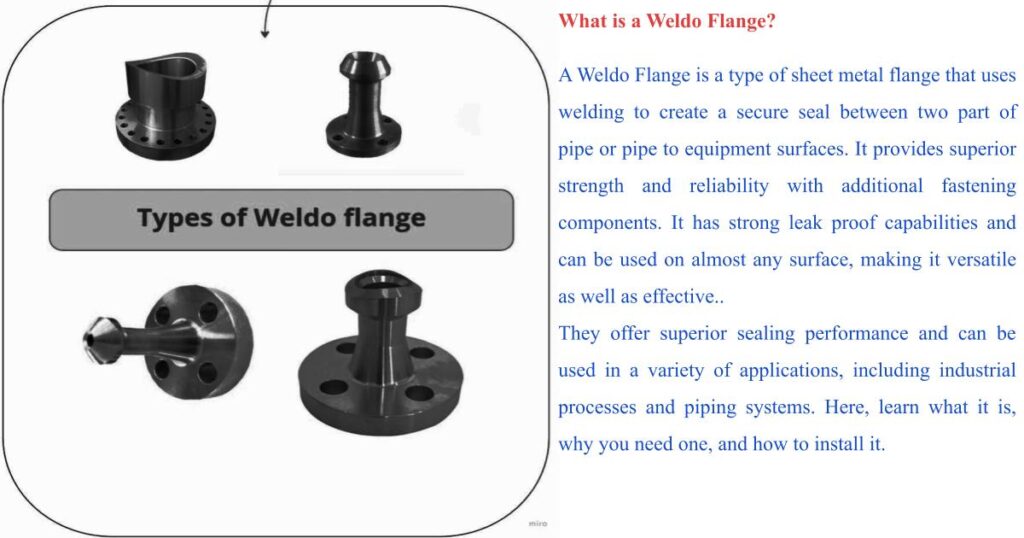

What is a Weldo Flange?

A Weldo Flange is a type of sheet metal flange that uses welding to create a secure seal between two part of pipe or pipe to equipment. It provides superior strength and reliability with additional fastening components. It has strong leak proof capabilities and can be used on almost any surface, making it versatile as well as effective. They offer superior sealing performance and can be used in a variety of applications, including industrial processes and piping systems.

Features of Weldo Flange

The Weldo Flanges are made of greater-quality carbon steel which offers superior tensile strength and ductility as well as corrosion resistance qualities. They also have also available with galvanized coated surfaces which increases their durability and extends their corrosion resistance properties even further in those corrosive environments they interact with. The coating also helps reduce erosion caused by destructive particles or fluids that come into contact with the weldo flanges while it’s in use.

Benefits Of Weldo Flange

The Weldo Flanges are very economical because they don’t require excessively long weld lengths which saves time and money when used for operation. Because most of these flanges are made of carbon steel, its cost over other exotic alloys such as stainless steels. Another great benefit of this range of flanges is that it comes with pre-painted coatings that improve its overall look and feel making them suitable for application.

Applications of Weldo Flange

Weldo Flange application mainly in industrial piping system for transporting liquids, gas, steam etc. And due to controlled temperature level across different industries like power plants, nuclear reactors, chemical industry wastewater medicine & food processing facilities plants oil & gas refineries etc.

These can be used on compressors, pump valves and among others too due to its exceptional performance abilities across arduous conditions. Where budget cutting aspects are also taken into consideration when constructing or installing new operations or upgrades as well as maintenance correctly over given periods/ timescales either short or long.

The Weldo Flange, made from ASTM B381 Titanium Grade 1/Grade 2/Grade 4 is a solid flange that offers a durable connection for piping and tubing systems. With increased corrosion resistance, tensile strength and higher resistance to fatigue, the Weldo flanges are an ideal choice for applications where durability is required.

This material is often used to facilitate strong and reliable connections between pipes in low-pressure piping systems. The addition of titanium offers strength and resistance to corrosion longer than traditional materials such as carbon steel, making it an ideal choice for applications in extreme environments.

The flange is made from titanium grade 5, as specified by the American Society for Testing and Materials (ASTM) b381 standard. It has excellent mechanical properties and strength characteristics, making it an ideal material for applications like automotive parts and frames, pressure vessels, and aerospace components.

Flanges are manufactured from ASTM B381 Titanium Grade 7, offering high levels of strength and resistance to corrosion. These flanges provide reliable connections for tube-to-tube fittings, as well as providing the necessary flexibility for process piping. The weldo flange is a cost-effective solution for applications requiring piping that must withstand extreme temperatures, cases of repeated vibration or regular pressure variations.

How to Install a Weldo Flange?

Installing a Weldo Flange requires a few simple steps. Before you begin, make sure the surfaces to be mated are clean and free of debris or foreign materials. Using a spotfacer, ensure the mating surfaces are properly aligned, and that the flange is properly centered on the surface. Place an appropriate gasket between the two surfaces and position the flange bolts in their designated location. When all preparations are complete, tighten each bolt to draw the two sides firmly together by using a torque wrench.

What Size and Type Should I Use?

Choosing the right size and type of Weldo Flange depends mostly on where it is being installed and what kind of connection that needs to be made. Generally speaking, most weldo flanges come in standard sizes, but it is important to check the specifications for the project you are working on to ensure that you have the correct measurements. Additionally, there are various types of flanges available depending on your purposes. Some materials work better than others depending on temperature, pressure, and corrosion resistance levels. Make sure you understand what kind of flange will work best for your particular application before beginning installation.

How Do I Inspect the Connections for Leaks?

Once your weldo flange has been properly installed, you will need to inspect the connection for any potential leaks. Leakage can introduce contaminants into the system and cause it to fail prematurely, so it is important to do this step carefully. Start by using a hand held bubble level to ensure that each side of the connection is even and level. Then use a leak detection fluid or gooseneck hose to check for airtightness. Finally, if you need to, you can use a pressure gauge or test kit to quantify how much pressure your connection is holding compared to its rated value.

Weldo flange specifications

The Weldo flange is a type of industrial pipework fitting used to join two sections of pipe. It is made from alloy steel, and its specifications include an inner diameter of 0.625 inches (1.59 cm), a surface finish of no less than 32 micro-inches RMS and a pressure rating up to 8000 lbs per square inch (PSI). The flange also has a taper rate that ensures proper seal when tightened with bolts.

Size Range

Weldo flanges are available in a wide variety of sizes, ranging from 1/2″ to 24″, depending on the manufacturer. The size determines the total length and weight of each flange, as well as the number of bolts required to secure it onto the pipe. Most weldo flanges are compatible with common pipe sizes and fit standard ASME B16.5 bolt circles, though they may come in non-standard variations depending on the application.

Pressure Ratings

Weldo flanges come in different pressure ratings, depending on their size and material, ranging from 150# all the way up to 4500# or higher. This denotes how much pressure the flange can withstand before it fails or deforms due to wear or corrosion. You should always match the pressure rating of your weldo flanges with that of your piping system in order to ensure adequate performance and compliance with relevant industry standards.

Bolt Patterns

Weldo flanges conform to either circular or oval shaped bolt patterns, typically denoted by A/N (American National) or D (European) standards respectively. Circular bolt patterns have bolts spaced evenly around its circumference while oval configurations have pairs of bolts located along two parallel sides instead. Depending on your application, you may require a specific type of pattern for proper installation and safety considerations.

Weldo flange materials

Weldo flange materials include carbon steel, stainless steel, aluminum, brass and bronze for both interior and exterior applications subjecting them to different chemical environments such temperatures related stress cracking or chloride attack resistance requirements needed by certain industries.

Torque Values

When bolting weldo flanges to pipes during assembly it is important that correct torque values are specified as part of good maintenance practice so make sure whichever torque value complying document you use has accurate information listed on it according to joint type being considered whether this being plain face joint bolts lined up uniformly across one side then working around in a clockwise direction ending up at where you started from; lap joint bolted from side one repeating this procedure along side two ; etc .

Finishes

High quality weldo-flange manufacturers offer many types of finishes for their products such as bare metal black plate finish; paint coated finish; galvanized hot dipped zinc plated finish & black oxide finish plus other protective coatings & layers that can be applied when requested

Weldo flange metarials specifications

-

Carbon Steel – Carbon steel is the most common type of flange material and provides excellent corrosion resistance, strength, and durability. It is also relatively inexpensive, making it a popular choice for pipe fabrication. It is ideal for manufacturing weldo-flanges made of stainless steel and alloy steels with their high-grade alloys that need higher working temperatures and pressure resistance.

-

Stainless Steel – Stainless steel has a higher level of corrosion resistance than carbon steel due to the addition of chromium during its production process. This makes it an excellent flange material for use in freshwater applications or highly corrosive environments, such as those containing harsh chemicals or poor quality waters.

-

Nickel Alloy Steel – Nickel alloys are the most expensive type of flange material available but have exceptional creep strength characteristics and offer excellent protection against acidic media; this makes them ideal for handling highly corrosive fluids at some of the highest temperatures possible in processing applications. These properties make them more suitable for manufacture as either standard forged weldo flanges or made in 3 pieces which reduce cost compared with alternative components manufactured from exotic materials including Monel, Hastelloy and Inconel which can provide your plant with reliable performance even under stressful environmental conditions like H2S service.

-

Bronze & Copper-based Material – Bronze and copper-based alloys are widely used in weldo flanges because they offer great resistance to corrosion when exposed to marine water or hot water whether they’re used in piping systems or valves with stagnant water inside them makes these alloys perfect for hygienic uses that require cleaning after each cycle ending like pure drinking water systems connected directly to people’s homes that must remain pure from dangerous contaminants – making weldo-flange pipes strong but flexible components within engineering designs despite having very low threshold values for fatigue strength when exposed to stress repetitiveness over time making it a strongly efficient mechanical component especially considering its resource efficiency when produced from existing scrap sources rather than bought raw (as long as it meets manufacturing guidelines).

-

Plastics – Weldo Flanges can also be made from plastics such as nylon 6/6 or PVC that’s reinforced with glass fibers adding an extra layer of protection. Thanks to their antioxidant properties which make them extremely competitive components when compared with plating solutions that require proper maintenance more consistently throughout extended periods as well as setting up entire electroplating lines just to keep up with daily demands thus reducing operational costs substantially.

- Plastic-made flanges are far easier to clean & maintain ensuring efficient hygiene practices within food processing plants than other industries demanding top safety standards. Thanks to its non corrosiveness even when submerged in water, it significantly lowers risk regarding leakages resulting in overall consumers reaping added benefits.

-

Aluminum & Aluminium Alloys – Aluminum offers superior tensile strength & ductility so not only can you easily shape & form any desired shape but welding these materials will be much easier allowing many different aluminum grades. This type extends high levels accessory products including bend joints flapping high pressures upon connection joints easing tensioning struggles where tech requirements demand changes on a regular basis.

- Low Temperature Carbon Steel (LTCT): These materials are specifically optimized for operation in temperatures below -20℃/ -4℉, giving superior strength even at extreme temperatures, making them ideal for cryogenic applications.

- Alloy Steel: Alloy steel offers higher strengths compared to carbon steel grades, and often exhibits improved impact properties compared with other steels due to its alloying elements like molybdenum or chromium which helps it resist impacts at lower temperatures or pressures.

- Monel: Monel is an alloy metal composed mainly of Nickel-Copper with additional elements like aluminum, manganese, iron etc. It has better tensile strength than stainless spaces, superior resistance to oxidation, and is particularly suited to high temperature environments due to its good thermal conductivity.

- Hastelloy: Hastelloy is a nickel-molybdenum alloy with excellent resistance to stress corrosion cracking and superior corrosion resistance across many types of media including various acids, alkalis and organic compounds along with chlorine atmospheres

- Duplex & Super Duplex Steels: Super duplex steels are the super heroes when it comes to pressure containment, due to their ability to maintain very high strength values over an extended range of temperature fluctuation as well as great formability properties which allows them to flexibly customize shapes of components like weldo flanges.

Weldo Flanges Code and standards

ASTM A105 Grade Flange

The ASTM A105 grade flange is a type of pipe flange and is used for piping systems with high temperature, pressure or corrosive fluids. These flanges are commonly found in oil & gas industries or in locations where rigidity and state regulations apply. The material used for the manufacture of this grade flange is carbon steel, as it helps prevent leakage from the pipe easily due to its superior strength and erosion resistance properties.

Benefits of Using an ASTM A105 Grade Flange

When using an ASTM A105 grade flange, you can enjoy multiple advantages over other types of pipe fittings including superior corrosion resistance when exposed to high temperatures, extremely high tensile strength that ensures durability even under extreme load conditions, excellent heat transfer characteristics which help to maintain process temperatures more efficiently, perfect compatibility with various fluids and materials as well as its ability to handle media pressures up to 20 000 psi (138MPa). Additionally, these fittings are lightweight compared to alternative materials meaning they are easy to install and cost effective in operation.

- ASTM A182 uses a forged ferritic stainless steel material with a very low carbon content to improve welding performance. This makes it an optimal choice for piping systems that must withstand extreme temperatures and pressures for extended periods.

- The material used to make ASTM A182 weldo flanges is highly resistant to corrosion making them ideal for use in corrosive environments such as chemical processing plants, refineries, power generation plants, and more.

- ASTM A182 weldo flanges are designed to have their opening size slightly larger than their nominal pipe size so they can accommodate thicker walled pipes easily when joining two sections together.

- These weldo flanges are designed for use in several different industries including oil and gas exploration and mining where the fastening of pipes may be needed to extract energy sources quickly and economically without risking cracking or leaking due to corrosion or heat fatigue caused by sudden changes in temperature.

- Since these weldo flanges come preformed with pre-cut holes, they can also be used in multiple applications without having to cut each one individually saving time and effort on the job site or fabrication shop floor.

- Lastly, depending on its intended application, ASTM A182 Weldo flanges can be customized by changing their material grade or pressure rating making them much more versatile than regular pipe fittings!

The ASTM A182 F304 is a type of Weldo Flange, which is typically made of stainless steel. It is used in a variety of applications and may have different styles such as a weld neck flange, threaded flange, integral flange or slip-on flange. These flanges are used to join pipes together and are highly durable, providing reliable service.

A Weldo Flange is a type of ASTM A182 flange made with stainless steel grade F304L. This grade is ideal for applications that are exposed to large temperature variations and wet atmospheres, making it an excellent choice for weld-and-repair type operations. The Weldo Flange features a 7/8″ raised face and is available in diameters ranging from 2″ to 24″.

Weldo- flanges are an ideal choice for any high-pressure or high-temperature application. They come in various sizes, pressure ratings, and materials, but one of the most popular types is the ASTM A182 weldo flange.

Introduction to Weldo Flange ASME SA350

Weldo Flange ASME SA350 is a type of flange designed for use in pressure vessel applications. This flange meets the Standards of Engineering Practice (SAE) requirements for fabrication and inspection according to the American Society of Mechanical Engineers (ASME). It is available in multiple sizes including Class 1-4, and 6 pounds up to 20,000 pounds for service temperatures ranging from -20 to +900F. The Weldo Flanges are used in both low and high pressure applications in industrial piping systems.

What Are The Advantages of Using a Weldo Flange?

A Weldo Flange offers many advantages, from its superior strength and reliability to its versatility and leak-proof capabilities. It can be used on almost any application with additional fastening components, making it a cost-effective option. This type of flange is also easy to install and uses less space than traditional flat or threaded flanges, which makes them perfect for tight spaces or areas that require a high level of precision.

- TYPES OF PIPE FLANGE

- SCREWED FLANGE

- BLIND FLANGE

- SOCKET WELD FLANGE

- SCREWED FLANGE

- SLIP ON FLANGE

- SORF FLANGE

- NIPO FLANGE

- LAP JOINT