What is flexible coupling?

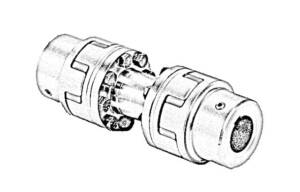

Flexible coupling is a type of coupling which is used for transmitting torque, power and connecting two different rotating machine shafts. Which are compensated for end movement of the shaft and rotate at the same speed.

It will also compensate for a little amount of misalignment (Angular and parallel) between both machine shafts if this small misalignment is not compensated for wear, tear and premature failure of equipment and its parts. In many causes it is used as a preventing device from damping vibrations to safe bearing and mechanical seal life.

Mostly this type of shaft coupling is used if both machines (meaning both machine shafts will be horizontal to each other or axially connected).

This type coupling will provide more parallel misalignment than other types and is easy to maintain and replace.

A flexible coupling needs more than one flexible element to accommodate angular offset.

but some elastomeric element couplings that can accommodate both parallel and angular misalignments of both machine shafts.

To save from internal rubbing, sleeve bearing is using some pump instead of thrust bearing.

There are some factors that can be disturbed by the proper alignment for both machine shaft like as thermal expansion,

Transfer hot or cold service liquid. But using flexible coupling is not a solution to all problems. It has its own limitations.

The two major misconceptions between coupling misalignment capacity and equipment misalignment tolerance with selectors should be clear before selecting suitable coupling. That will cover another chapter.

What are the Functions of Flexible Couplings?

The important functions of Flexible Couplings is describe below and some of them have already been explained in details in the above section.

- Dampen vibration, reduce peak and shock loads

- Protect both machines from overload

- Measure the output torque of driven machinery

- Isolate the driver from the driven machine

- Position a rotor of a motor or generator and another machine

- Be used to tune a machinery system out of a rotational critical mode

|

How many types of flexible coupling?

Type of flexible coupling categorized depends on the purpose of uses, these are followings.

- Flexible coupling

- General purpose

- Special purpose

- mechanically flexible type

- General purpose flexible type

- Gear type (Straight teeth gear)

- Chain type (chain type steel), chain type nylon

- Grid type coupling (Verticall split grid type and horizontally split grid type)

- Gear coupling is used for high speed and high torque applications.

How to select appropriate flexible coupling?

Selection procedure to identify the requirements for equipment operation and select the type of coupling which will be best suits your system,

Horsepower requirement for operate, Operating speed RPM, Interface connect information, fitting of hub, Torques required to operate and first, minimum and greatest torque produced by driver, Angular misalignment, Offset misalignment, Axial movement, Ambient temperature of equipment during operation, Potential excitation or critical frequencies (Torsional, Axial, Lateral) Limitation on that coupling-generated forces (Axial, Moments, Unbalance) Any other unusual condition or requirements, and Space limitations (drawing of system showing coupling, envelope), eristics-weight, torsional stiffness.

Standard for balancing specification of coupling

AGMA 9000 flexible coupling potential and balance classification

API 671 limitations

Where to classes comment on the API that is following low speed coupling? In this criteria, the equipment RPM is approx 1800.

AGMA 9 High speed coupling over 1800

Speed class specification accordingly low speed is less than 2300 intermediate or medium speed, considered as greater than 2300 rpm but for high speed is always greater than 3200.

How many types of clearance is required to fit coupling in the shaft?

There are three types of clearance required to fix flexible coupling in the shaft.

Clearance fit or loose fit in this type of fit. The clearance between inner bore of coupling and outer bore of shaft is in plus and is provided by the vendor. This type of clearance fit is used with approx 150 HP. drivers only and the AGMA 9002 is used for balancing purposes.

Interference fit This type of fixing coupling also comes in AGMA 9002 accordingly it is used for more than 150 HP equipment. Set screw type coupling, fix the key fitted in the shaft and coupling.

How to install the coupling in the shaft of equipment?

Before the installation you should have to check physically if cracks are any other damage in coupling. Then after, you should have to check ID, OD and roughness of internal bore and shaft of equipment. If any roughness is observed in any of the equipment shafts, clean the roughness. Lastly, if you have a manufacturing installation manual you should have to follow the same. Or you have also required an installation manual supplied by the manufacturer.

The coupling is stored for a long time as a spare as we put the installation check erosion and corrosion for the same and before the store any equipment should have to apply in oil, grease or wax type material to save from the corrosion. Before installation clean the shaft, the coupling has to be fixed and coupled inside the boss as well as the key parameters that have been to measure before installation required bore dimensions, key thickness, length of the coupling, distance between shaft end (DBSE) of equipment’s, diameter of and other dimensions prescribed by manufacturers.

YOU CAN ALSO LEARN BY MORE TOPIC BY FOLLOW LINKS

- What is coupling, types, and its application – Parts 1

- Rigid coupling and its types -Parts 3

- Fluid coupling, types, and benefits – Parts 4

- Grid coupling and advantages – Parts 5

- Gear coupling and uses – Parts 6

Wonderful blog! Do you have any helpful hints for aspiring writers? I’m hoping to start my own blog soon but I’m a little lost on everything. Would you recommend starting with a free platform like WordPress or go for a paid option? There are so many choices out there that I’m totally confused .. Any suggestions? Appreciate it!