What is pipe elbow?

Elbow is pipe fittings, that are used to change the direction of pipeline routes for fluid flow. It is one of the most common types of pitting and generally used in every pipeline in plant or outside plant as well. This is available many in different angles – like 45°, 90°, and some special 22.5° angles – by cutting the standard available elbow (45°, 90°) in another degree as well, as per user requirement. Elbow is available in two radius lengths, such as short radius (45°) and long radius (90°) elbow. 90° elbow (90° ell) are also called quarter bend elbow also, because the flow is redirected to one quarter of 360° that means 90. But due to sudden redirect of fluid flow rate and pressure within the pipe, the elbow will be dropped. That is only one disadvantage of using the elbow in industries pipeline.

The material (service fluid) under pressure hits the internal surface of the elbow and continues flow in change direction, it meets the resistance of the elbow internal wall, due to forcefully changing direction. The internal length of the elbow plays an important role in flow resistance. A quarter bend (short radius) elbow creates more pressure drop as compared to long radius types, because the transferring material received sudden flow diverted in another direction. There are some short words (term) use for elbows, like center-to-face dimensions of 1x of pipe size are called short radius and 1.5x is called long radius respectively. This is also used to connect two pipes of the same or different diameter pipe

The fluid moving very fast within the fitting and creates a smoother transition for the material, and it advantages is less turbulence in the pipeline system. Generally, a long radius elbow is used when flow rates and pressure are more important than the plants area optimized design. 45° and 22.5° long radius bend have less pressure drop than 90° bend. A variety of elbow connections are available, including threaded, weldable, socketed and flanged. When it comes to threaded elbows, male and female connections are most common. However, come in male-x-female elbows, they mostly use the same size connection on both sides. If one end is smaller than the other end connection is called a reducing elbow. This is used with careful, as the change in pipe diameter will result in a change in pressure and velocity of the fluid. All of the above-mentioned factors should be considered when selecting the right elbow for your application and project.

Equivalent length of the pipe elbow

Equivalent length of pipe elbow is a calculated by numeric value that converts the friction losses associated with bends or elbow fittings and fluid velocities to representative length of pipe elbow and diameter.

Note – The following values in the chart are Le/D ratios. Please be careful of this when comparing various data sources. You might be aware that many authors including me sometimes refer to the Le/D ratio, instead of the more correct Equivalent Length / Diameter Ratio.

Following charts of Equivalent Lengths (Le/D) for Plastic and Steel Pipe elbow fittings

| Pipe Elbow | Rigid PVC/HDPE e = 0.005 mm |

GRP/FRP e = 0.02 mm |

Commercial Steel e = 0.05 mm |

Spiral Weld Steel e = 0.1 mm |

|---|---|---|---|---|

| Threaded end Joint Elbow | ||||

| 90 Degree 1/2 elbow, r/d=1 | 37 | 34 | 30 | 26 |

| 90 Degree 1/2 elbow, r/d=1 | 37 | 34 | 30 | 26 |

| 90 Degree ½ elbow Welded end Joint Elbow | ||||

| 90 Degree ½ elbow, sharp bend | 69 | 63 | 55 | 49 |

| 90 Degree ½ elbow, r/d=1 | 23 | 21 | 19 | 16 |

| 90 Degree ½ elbow, r/d=1.5 | 17 | 15 | 13 | 12 |

| 90 Degree ½ elbow, r/d=2 | 14 | 13 | 11 | 10 |

| 45 Degree ½ elbow Welded end Joint Elbow | ||||

| 45 Degree 1/2 elbow, sharp bend | 22 | 20 | 18 | 16 |

| 45 Degree 1/2 elbow, r/d=1 | 17 | 16 | 14 | 12 |

| 45 Degree 1/2 elbow, r/d=1.5 | 12 | 11 | 9.4 | 8.3 |

Types of elbow in piping

The types of pipe elbow categorized on the base for the following point some of them are described below.

On the base of end connection types

- Bevel end connection types

- Plain end connection types

- Threaded end connection types

On the base of end joint connection with pipes

- Socket welds joint

- Butt welds joints

- Threaded joint

- Male female connections

On the base of radius types

- Short radius Elbow

- Long radius types

On the base of elbow and pipe end connection

- Full bore elbow

- Reducing bore elbows

On the base of pipe elbow angles standards elbow or non standard

- 45 degree bend pipe fitting

- 90 degree bend pipe fitting

- 60 degree bend pipe fitting

- 120 degree bend pipe fitting

- 180 degree bend pipe fitting

- 22 degree bend (Non standards bend)

Wall Thickness of Elbows

Material of Construction

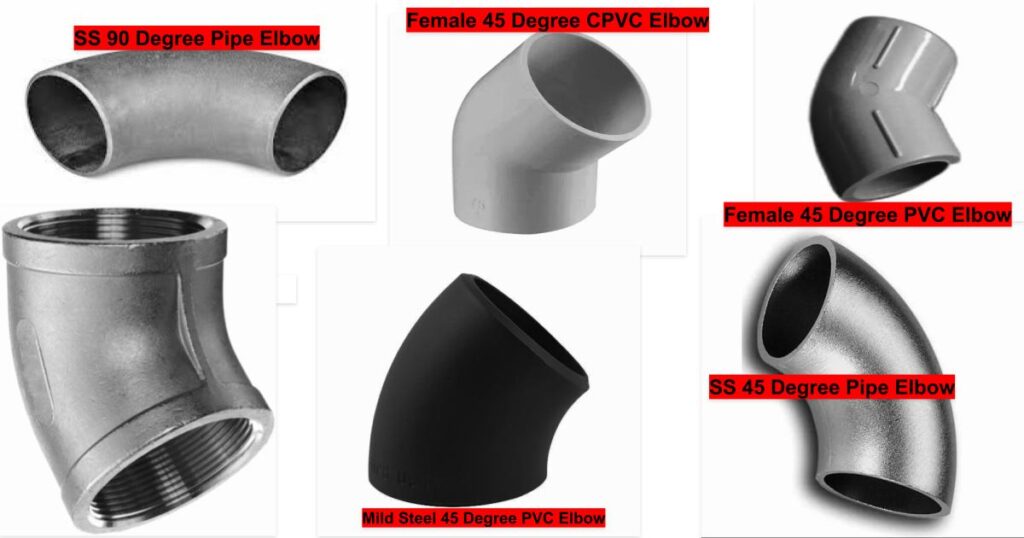

Types of Elbows based on Material of Construction described as below.

Steel pipe elbow

Steel pipe elbow is made from steel materials to get better strength for plant piping. Because steel straight is more than other types of material. Generally steel pipe elbow is used in process plants like, chemical, oil and gas, petrochemical, pharmaceutical and other. A variety of materials used to construct steel elbows like Mild Steel, carbon steel, stainless steel and others. It is also available in a variety of end connection types like threaded end, butt weld, socket weld, bevel end, plain end etc.

This is available with two types of fabrication types like as

- Seamless

- ERW (ERW further classified in two types straight welds and spiral types)

Seamless elbow can be used with high pressure and high temperature services line hot water, steam HP, LP, LLP and condensate. There are two types of processes used to fabricate bends seamlessly, fabricated and ERW (electrical resistance welding) process. The following process in manufacturing is used to make elbows by Push, Press, Cast, Forge.

Pipe elbow prices

The price of elbows may change materials to materials and manufacturer to manufacturer as his brand valve. You can find here the best elbow for your appropriate application at a very reasonable price by clicking here……

Pipe elbow 45 degree

45 degree pipe bend is most preferred for reducing the pressure drop in the pipe line by cutting the standard 90 degree bend in two parts or two 45 degrees from them.

pipe elbow fabrication formula pdf

pipe elbow joint

Pipe bends joints are totally dependent on services pressure, temperature and cost. There are many types of joints available nowadays, these are as below socket welds, butt welds, threaded joints, sliding fit, male female and other also.

PVC pipe elbow

PVC elbow or bend is the same as other metallic elbows, but it is constructed with PVC ( polyvinyl chloride). This allows allow to redirect the flow in another direction like 90 or 45 degrees or may be others. That is use for low pressure and temperature services like home plumbing for where needed to avoid existing structures or modification in the home or access outside lines.

The sizes of PVC fittings represent the inside diameter (ID) of the fitting, it is also called the ‘bore’ of the fittings. The outer diameter is fixed for pipe elbow only. ID will change with schedule number. As the schedule number is increased. The fittings internal diameter also decreases accordingly. The marks or hard punch on the pipe or fittings represent details and information of the fittings, which mentioned the following details should be like size, pressure class, metrology and thickness.

How to make long elbow bends by cutting pipe and weld?

The long elbow bend is fabricated by pipe cut at an angle in many parts and then assembles all with tack welds at all parts to each other by sequences. And then final welding performed pipe ends to each other for all cut pieces to make a required bend generally at 45° and 90°. But this method is not used for high temperature and pressure services.

The following formula is used for make complete bends

Inputs Required for Miter Bend Calculation are as follows: Bend Diameter, Bend Radius, Bend Angle, No. of Parts, No. of Development Lines

Calculation Steps

Step 1: Draw the sketch as number of cuts

Step 2 : Calculate the miter offset and angle cut

Miter offset () = Bend angle Number of cuts, = (90/4), =22.5 degree

Angle of cut () = Miter offset /2, = 22.5/2, = 11.25 degree

Step 3: Now calculate the length L1, L2, L3 and other with the help of the angle of cut and so on……..

GI pipe elbow are designated

GI elbows are designated as galvanized iron pipe elbow, this is different from MS bend, generally best suitable for corrosive environment. Generally there are many types of elbow available, like ERW, seamless and miter bend types.

Can you weld a slip on flange to a 90 degree elbow?

In some spatial cases, it can do but this is not a standard practice because most of the chances are leakage and not fitted properly.

Is this possible to check dye penetrant test in 15 NB pipe with socket coupling or elbow?

Yes

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.